7 Inventory Mistakes That Cost Small Businesses Thousands — and How to Fix Them

Inventory mistakes are easy to overlook until they start costing you money. A few late shipments or unsold items piling up in storage might seem minor at first, but they can quietly eat into your profits. Small businesses often don’t realize how much is lost to poor inventory practices until it’s too late.

One global study found that inventory distortion, including overstocking and stockouts, costs retailers $1.77 trillion every year. Even a small piece of that can seriously affect a growing business.

In this article, we’ll walk through the most common inventory mistakes and show you how to fix them with simple, proven steps.

What’s Causing Inventory Loss in Small Businesses?

Inventory problems don’t usually happen overnight. For most small businesses, they build up quietly—one missing shipment, one miscounted item, one spreadsheet error. These issues might not seem urgent in the moment, but over time, they chip away at your margins and make it harder to grow.

Unlike large retailers with dedicated teams and complex systems, small businesses often rely on manual processes, outdated tools, or informal communication. That makes them especially vulnerable to costly mistakes.

Some of the most common causes include:

- Tracking inventory by hand or in disconnected spreadsheets

- Underestimating the impact of seasonality and sales trends

- Poor communication between team members or departments

- Uncertainty about what’s actually in stock, what’s reserved, and what’s incoming

- Delaying the switch to a dedicated inventory system

The good news is that most of these issues are avoidable. Once you recognize where the breakdowns happen, it becomes much easier to fix them.

7 Costly Inventory Mistakes (and How to Fix Them)

These are some of the most common mistakes small businesses make when managing inventory. Let’s walk through each one—and what you can do to prevent them.

1. Using Spreadsheets to Manage Inventory

🔴 The Problem:

Spreadsheets are fine at first. They’re familiar, easy to set up, and free. But as soon as your business has more than a few items or team members, errors start to show up. Someone forgets to log a sale. Another person updates the wrong version. You end up with outdated information that leads to bad decisions.

🧾 Real-World Example:

A local coffee roaster ordered an extra batch of beans because the spreadsheet hadn’t been updated with the last shipment. Not only did they overspend, but they also had to rush to find storage space for the excess inventory.

✅ What to Do Instead:

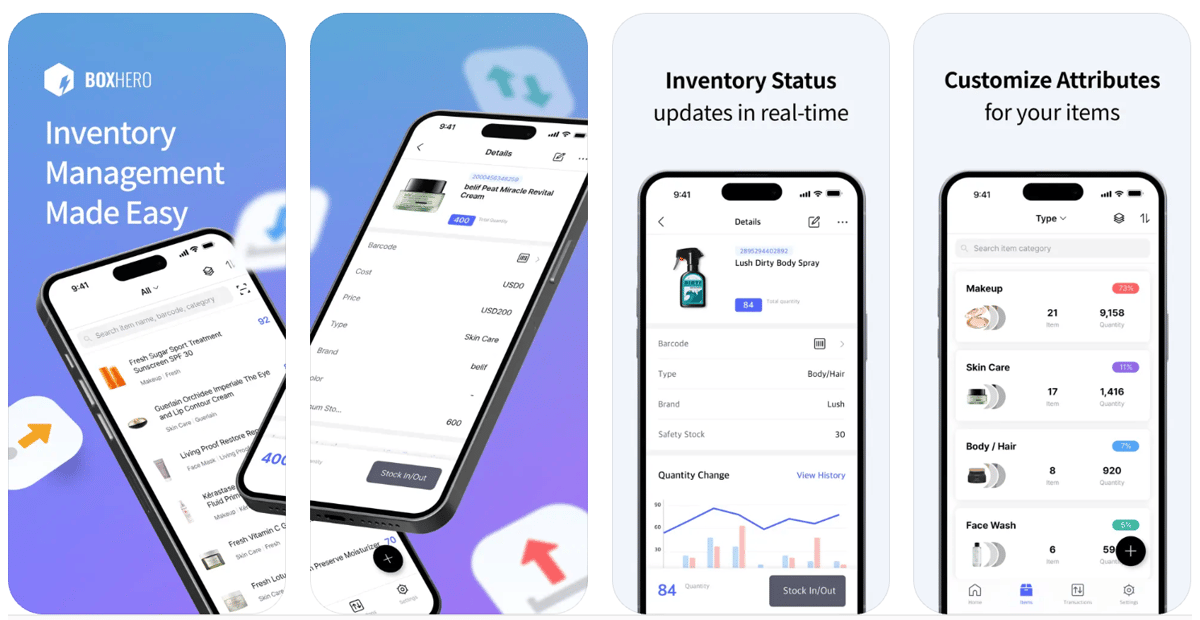

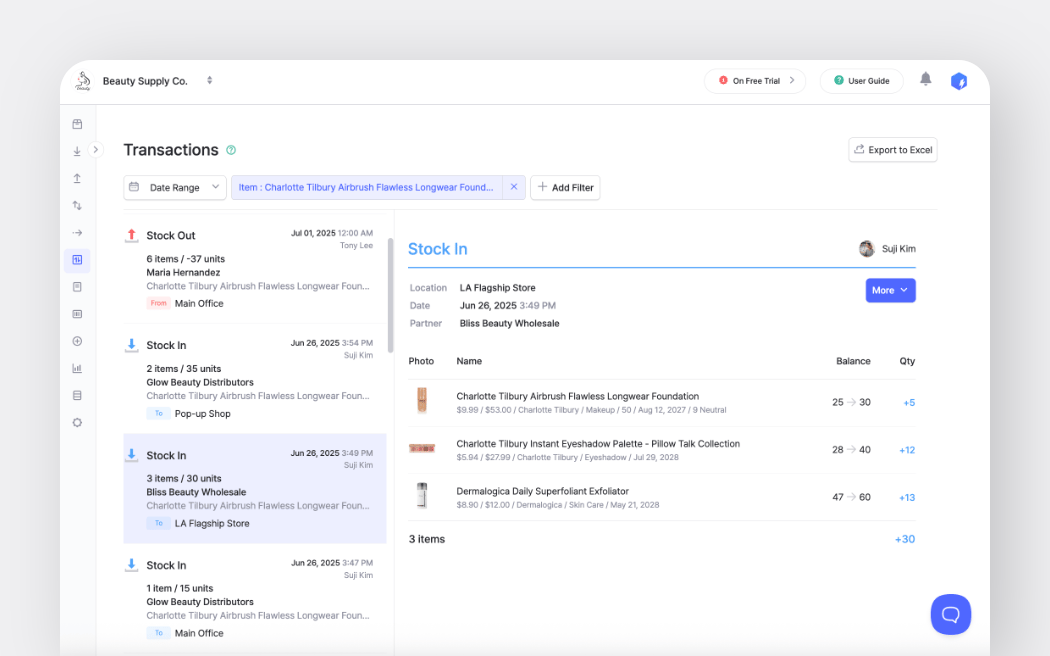

Switch to an inventory system that automatically updates in real time. Look for one that works across devices so your team can log changes from anywhere. Even a basic setup that tracks stock levels and sales activity in one place will save time and prevent costly duplication.

2. Not Planning Stock Levels Properly

🔴 The Problem:

Overstocking ties up your cash, and understocking causes delays and missed orders. Many small businesses don't have a clear system for planning how much to keep in stock, and that unpredictability can become expensive.

📉 Data to Know:

One survey found that 34% of businesses had to ship an order late because a product was unexpectedly out of stock.

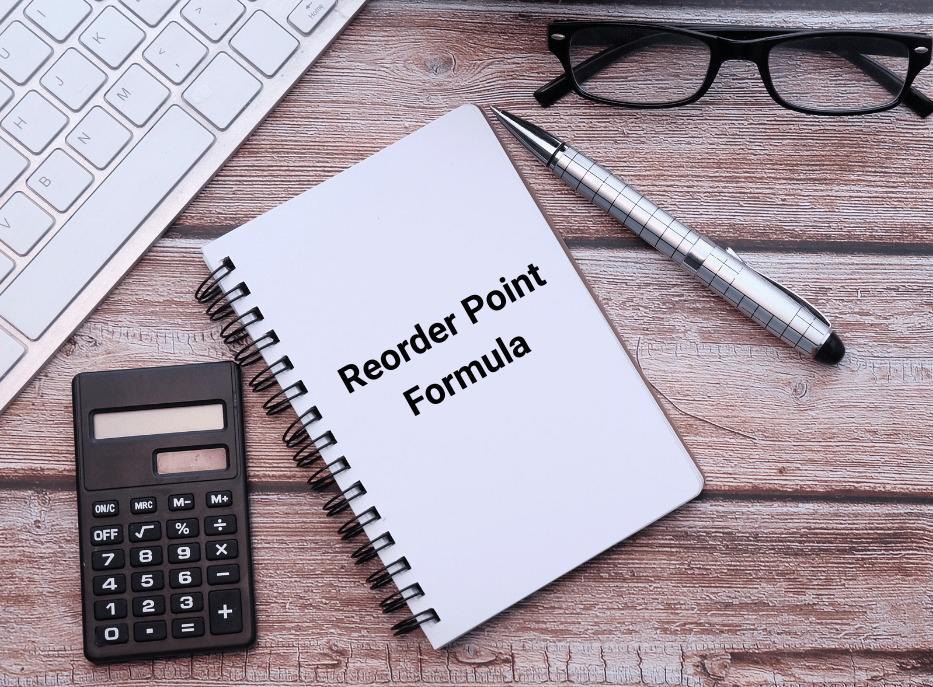

✅ How to Fix It:

Set reorder points based on past sales data. Use sales velocity to predict how long stock will last, and add buffer time for restocking. When possible, build automated alerts that tell you when it's time to reorder. This helps avoid both excess and shortages.

3. Ignoring Seasonal Trends

🔴 The Problem:

Buying the same quantity of inventory year-round often leads to waste or missed demand. Small businesses sometimes overlook seasonality, assuming it doesn’t apply to them. But even subtle trends can add up.

🧾 Real-World Example:

A pet supply store stocked up on winter dog jackets in January and struggled to sell them once spring arrived. Meanwhile, they ran out of flea treatments just as demand was rising.

✅ How to Fix It:

Review past sales by month and look for patterns. Talk to your suppliers about lead times during busy seasons. Align your purchasing with marketing campaigns and holidays. Even a rough seasonal calendar can help you order smarter.

4. No Item-Level Tracking

🔴 The Problem:

When you treat inventory as a lump sum, you lose track of important details. This is especially risky for perishable items, regulated goods, or products with variants. Without tracking by lot, serial number, or expiration date, it's hard to catch issues before they cause loss.

✅ What to Do Instead:

Implement item-level tracking for anything that requires expiration management, traceability, or version control. Make it easy to pull up item history during audits or inspections. This is particularly helpful in industries like food, cosmetics, electronics, or medical supplies.

5. Poor Communication Between Teams

🔴 The Problem:

When operations, purchasing, and sales teams work from separate tools or documents, information gets lost. One team may think an item is available when it’s already committed elsewhere. Miscommunication leads to delays, customer complaints, and lost sales.

🧾 Real-World Example:

A small wholesaler had sales reps confirming availability with clients before checking with the warehouse. As a result, they oversold multiple items and had to refund orders, which damaged long-standing relationships.

✅ How to Fix it:

Use a shared inventory system that gives all teams access to the same real-time information. If possible, integrate it with your sales or order management tools. Hold quick weekly check-ins to flag inventory issues before they snowball.

6. Skipping Regular Inventory Counts

🔴 The Problem:

Inventory rarely matches what's on paper without regular checks. Discrepancies build up over time and go unnoticed until there’s a serious issue. Skipping audits also makes it harder to identify theft, damage, or administrative errors.

📉 Data to Know: Businesses lose an average of 1.5% of revenue every year to inventory shrinkage, according to the National Retail Federation.

✅ What to Do Instead:

Schedule regular cycle counts, even if you don’t do full physical counts often. Focus on your highest-value or fastest-moving items first. Compare system records with actual inventory and track discrepancies over time to spot patterns.

7. Waiting Too Long to Upgrade

🔴 The Problem:

Many small businesses wait until things go wrong before investing in better tools. The common excuse is “we’re not big enough yet.” In reality, most inventory problems start when things are still small—and grow from there.

✅ What to Do Instead:

Start with a basic inventory system early. You don’t need all the features of a large ERP. Look for something that handles item tracking, reorder points, user roles, and reporting. The right system will scale with you as your business grows.

How to Avoid These Issues Long-Term

Fixing day-to-day inventory problems is a good start. But the bigger opportunity is building habits and systems that prevent them from happening in the first place.

The most common mistakes like missed updates and overordering usually come down to one thing: not having a clear, reliable way to track what’s in stock, what’s reserved, and what’s on the way. As your business grows, the risk of small errors multiplying gets even higher.

Here’s what helps small businesses stay ahead of inventory problems over time:

▶︎ Use a dedicated inventory system.

Instead of spreadsheets or paperwork, use a dedicated inventory software. Even a simple tool that tracks item counts, sales activity, and restocks in one place makes a big difference.

▶︎ Keep your inventory data accessible to your whole team.

When sales, purchasing, and operations all rely on the same information, you’re much less likely to run into surprises.

▶︎ Build time for regular checks.

Set a weekly reminder to review stock levels, reorder alerts, or recent changes. It doesn’t need to be complicated—just consistent.

Good inventory management is about setting up simple systems that help you can catch issues early and adjust quickly, so your business can keep moving forward.

Key Takeaways

Inventory mistakes are often small at first, but they grow quickly if left unaddressed. By recognizing these common issues and taking simple steps to fix them, you can avoid unnecessary losses and build a more resilient business.

If you’re still relying on spreadsheets or juggling tools that are disconnected, now is the time to change that. You don’t need a complex system to see real benefits. Even small changes—like tracking reorder points or syncing with your team—can make a big difference over the long term.

With BoxHero, you can start tracking inventory as a team in minutes, without needing to learn a whole new system.

RELATED POSTS