Cycle Counting vs. RFID vs. Manual Audits: What’s Right for Your Inventory?

Inventory accuracy quietly drives everything: what you buy, what you ship, and what you can sell. When records are off, you get stockouts, write-offs, and financial reporting problems.

The challenge has only grown. Customers expect accurate availability across online and in-store channels, while businesses face tighter margins and less room for error. Shutting down once a year to count everything may no longer be enough.

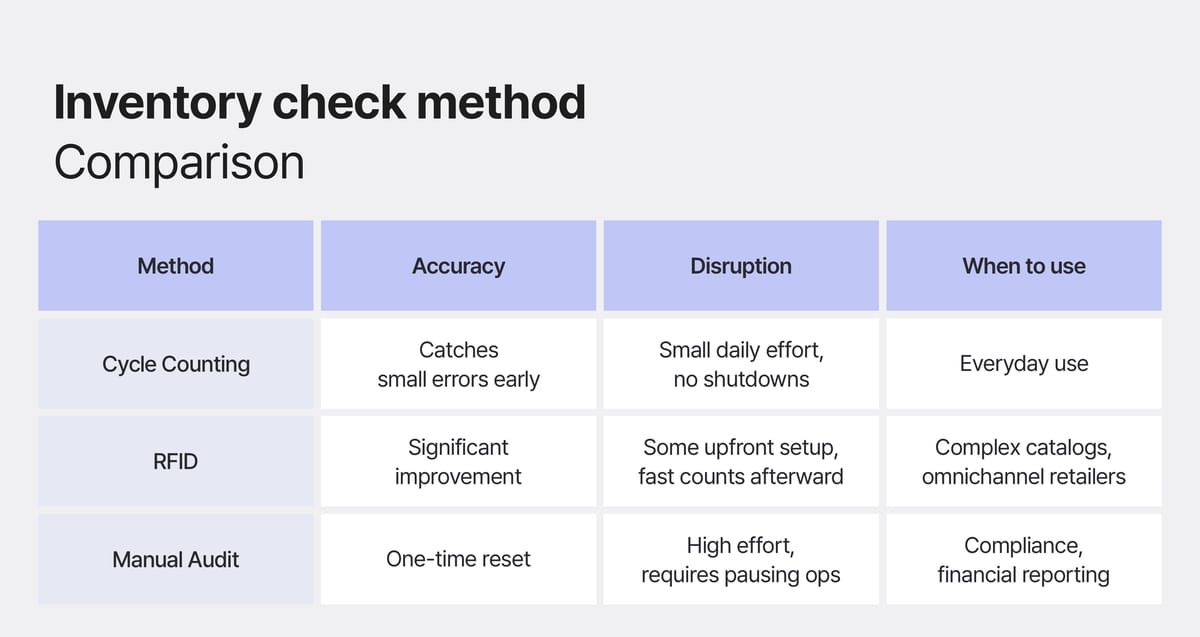

That’s why it helps to understand the main approaches to inventory checks today: cycle counting, RFID, and manual physical audits. Each comes with its own balance of accuracy, cost, and disruption. In this guide, we'll help you choose the right one for your team based on your inventory catalog.

Quick Definitions

Before comparing methods, let’s get clear on what each method actually means:

- Cycle Counting

Instead of stopping everything to count your whole warehouse once a year, cycle counting means checking a small set of items on a regular schedule. Over time, this keeps accuracy high without bringing operations to a halt.

- RFID

RFID uses small tags that send out a unique signal, allowing a reader to scan many items at once. You don’t need to see or touch each tag like you would with a barcode. It’s faster and can improve accuracy, especially in stores or warehouses with lots of similar items.

- Manual Physical Audit

This is the traditional “all at once” method. Teams stop operations to count every single item, often at the end of the year or during an external audit. It gives a complete picture but can take a lot of time and usually interrupts normal work.

Compare & Contrast

1. Cycle Counting: steady, small steps that add up

How it works

Essentially, you create a schedule—often based on item importance—and check small groups of items regularly.

Why it’s popular

- You don’t have to shut everything down. A few counts a day keep things in order. It's a major advantage over annual audits.

- It prevents small mistakes from turning into big ones. If receiving misses a few items, you catch it before it cascades into reorders or shortages.

- It fits with barcode scanning workflows. If your team already scans barcodes, cycle counting is a natural next step!

Best practices

- Use an ABC schedule: count fast-moving or high-value items most often, and slower items less frequently. For example, count A items weekly or monthly, B items quarterly, and C items semi-annually.

- Always investigate variances, not just adjust numbers. Was it a mis-scan? Wrong unit of measure? Misplaced bin? Capture reasons like receiving lag or pick misses and review weekly.

- Apply closed-loop fixes: if one area keeps going wrong, change the process, not just the count.

“The most effective cycle counting programs reflect the realities of managing inventory in a dynamic environment.”

— ASCM guidance on cycle counting

2) RFID: speed and accuracy

How it works

RFID tags carry unique IDs that can be read without line of sight.

- A handheld reader can sweep an area in minutes, and

- Fixed readers can track items moving through a dock door or aisle.

What the data shows

- Multiple studies and industry groups report big jumps in accuracy. Companies typically move from 65–75% to 93–99% with RFID implementation.

- GS1 US notes item-level RFID programs often achieve 95% accuracy, which barcodes alone rarely sustain.

Where RFID fits best

- Retailers with many size, style, or color variants (apparel is a leading example).

- Businesses promising buy-online-pickup-in-store or ship-from-store, where inaccuracy means breaking a customer promise.

3) Manual audits: thorough but disruptive

What they are

The classic full count (of every item and location), usually once a year for auditors or financial reporting.

Pros and cons

- You get a clean, comprehensive snapshot. Useful after a big system migration or when you need to reset everything.

- Time-consuming and disruptive, with many companies needing to pause operations for days. That carries real opportunity costs, especially during busy seasons.

Practical use

Use a full physical when you must (compliance, external reporting, major resets). For the rest of the year, rely on cycle counting and targeted recounts.

How to Choose the Right Method

Ask yourself a few questions to figure out which approach fits your team best:

1. Are you required to perform a year-end physical?

If yes, plan the physical, but design cycle counts so you don’t need a shutdown outside of that.

2. Are stockouts and mis-picks hurting your catalog?

If you carry many size/color variants or run omnichannel promises like same-day pickup, RFID’s lift in location-level accuracy deserves a pilot.

3. Do you have the staff for daily checks?

If you have don't have enough team members, RFID handheld sweeps can cover more ground; otherwise, a tight cycle-count schedule is often enough.

4. What’s your current accuracy?

If you don’t know, run a baseline: pick 100 SKUs, count them, compare to system.

- If accuracy is below 90%, start with cycle counts and process fixes.

- If you need a fast leap to 95%+, consider RFID.

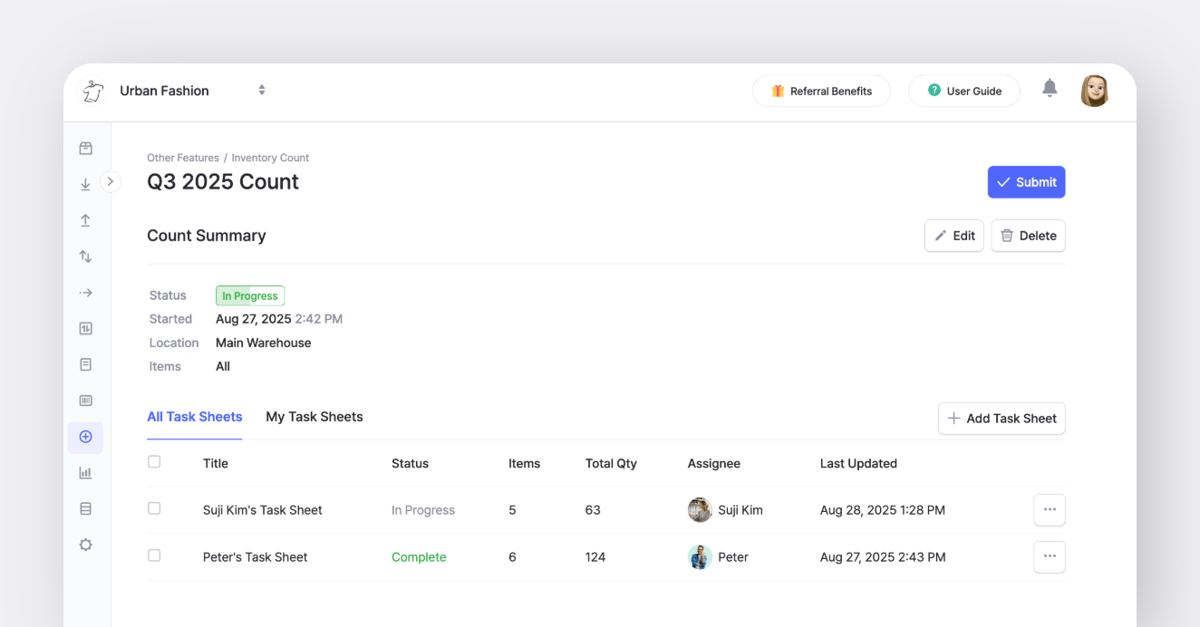

BoxHero's Role in Counting

For most small and mid-sized teams, cycle counting with barcodes is the most practical place to start. BoxHero helps you:

- Schedule and run frequent small counts instead of shutting down once a year.

- Assign members to task sheets so staff can count while managers review and approve adjustments.

- Keep a clean audit trail by capturing variance notes and who approved them for accountability.

BoxHero offers a free Personal Plan for individuals and a Business Plan with monthly or annual options (which includes a 30-day free trial to test all features).

Best Practices Come from Habits

Technology helps, but habits keep records clean:

- Receive before you pick. No back-dating entries.

- One bin, one item for fast movers.

- Label everything: bins, cases, and inner packs.

- Record variance reasons and review them.

- Track KPIs: compliance, variance rates, and top error causes.

Over time, these practices reduce shrink and waste.

For context, a 2023 survey by the National Retail Federation reported average shrink of 1.6% of sales—real money that better controls can chip away at.

Next Steps

- If you want reliable counts without shutting down, start with cycle counting. Build the habit of investigating errors, not just correcting numbers.

- If your catalog is complex or you promise omnichannel speed, test RFID in one category and measure the results.

- Keep manual audits for compliance and major resets.

A simple starting plan:

- Use BoxHero’s free 30-day trial to set up a cycle count.

- Track variances and reasons for four weeks.

- If accuracy still isn’t where it needs to be, try piloting RFID in a problem area and measure before/after results.

RELATED POSTS