How HVAC Teams Organize Inventory: Parts Tracking

HVAC service work depends on having the right parts available before the day begins. Technicians move between calls quickly, and the difference between a complete repair and a return visit often comes down to a capacitor, a motor, a relay, or a fitting that should have been on the truck. These small details add up, especially during peak seasons when schedules fill fast.

The Air Conditioning Contractors of America (ACCA) notes that manual inventory processes are “laborious and prone to errors,” and technicians feel those gaps immediately when a service vehicle leaves the shop without the essentials.

This article looks at how HVAC teams organize inventory across vans and warehouses using real examples. It also shows how motors, sheet metal, installation materials, and other HVAC items can be grouped and tracked cleanly in a system like BoxHero.

Why HVAC Inventory Is Harder Than It Looks

Heating and cooling systems require a combination of large equipment, consumable materials, electrical components, and brand-specific parts.

HVAC teams work with items that vary widely in size, usage frequency, and manufacturer, which naturally creates friction in daily work.

A. Parts are dispersed in multiple places

It’s hard to know where things actually are. Most small service teams keep inventory in at least three locations:

- The main shop or warehouse

- Service vans

- Job sites and temporary staging areas

When parts shift between these locations, it becomes harder to keep accurate counts. Missing components and last-minute supply-house runs can disrupt the entire day for HVAC technicians.

B. Small components move constantly

Capacitors, fuses, filters, valves, and fittings... HVAC repairs often require inexpensive but essential parts and components. For example:

- 4×5 sheet metal

- 6" furnace stands

- 25×15 return cans

- Motor assemblies

- Blower motors

- Dual-shaft 1/8 HP motors

These items are used frequently during both service and installation work. When they are not organized or counted, they fall out of sync as technicians restock their vans, pull items for jobs, or grab supplies during the day.

C. Seasonality changes everything

Summer cooling and winter heating seasons create natural surges in HVAC work. Many contractors report heavier summer workloads, especially during heat waves or prolonged high temperatures (Death Valley, CA hit 127°F in July 2024 🥵).

These spikes put pressure on both technicians and inventory. Fast-moving parts get used up quickly, and teams often underestimate how much stock they will go through when the extreme weather pushes equipment to its limits.

D. Manufacturer-specific parts accumulate

HVAC systems vary widely by brand. Every manufacturer—Carrier, Lennox, Trane, Goodman, Daikin—uses its own combination of boards, sensors, motors, or control components.

HVAC shops often keep extra parts “just in case,” and over time they end up with shelves of outdated or mismatched items.

Best Practices HVAC Teams Use to Organize Inventory

HVAC teams that keep inventory under control follow a few consistent habits. These practices are practical, repeatable, and based on what actually helps technicians stay prepared.

1. Track parts at the van level

Every service vehicle becomes its own mobile inventory location. The most effective HVAC teams treat vans as individually managed stock areas rather than an extension of the warehouse.

Vans typically carry:

- Capacitors

- Contactors

- Fuses and relays

- Basic thermostats

- Blower motors for common models

- PVC and copper fittings

- Fasteners, brackets, and installation hardware

- Sealants, tapes, adhesives

2. Use targeted restock lists

Rather than broad “truck stock” spreadsheets, leading HVAC shops maintain practical lists focused on the parts technicians use every week. That way, they can focus on the core consumables like:

- Common capacitor sizes

- Single- and double-pole contactors

- Assorted fuses

- Basic thermostats

- Refrigerant (tracked by cylinder)

- PVC fittings

- Copper fittings

- Drain pan treatments

- Zip ties, screws, tapes, and adhesives

3. Prep installation jobs with pick lists

Installation work relies on predictable sets of materials. Pick lists reduce the chance of missing hardware during an AC, heat pump, furnace, or mini-split installation.

A sample AC installation pick list includes:

- Condenser

- Air handler

- Thermostat

- Line set

- Pad or bracket

- Disconnect

- Whip

- Breaker

- Sheet metal

- Return cans

- Furnace stands

- PVC and drain components

4. Use a simple BOM for installation types

While service calls rarely require a bill of materials, installations benefit from a consistent BOM. In HVAC, it helps teams gather everything needed for:

- Furnace installs

- Heat pump installs

- Mini-split systems

- Rooftop unit replacements

A BOM reduces missing components and clarifies what needs to be ordered in advance, especially when lead times are uncertain.

5. Track supplier details & lead times

OEM part numbers and equipment compatibility are stored directly with each item. HVAC teams also benefit from noting:

- Preferred suppliers

- Typical lead times

- Price ranges

- Order frequency

Small teams track these informally, but a better method is to note typical lead times in your inventory system or purchasing notes.

BoxHero Tips for HVAC Use Cases

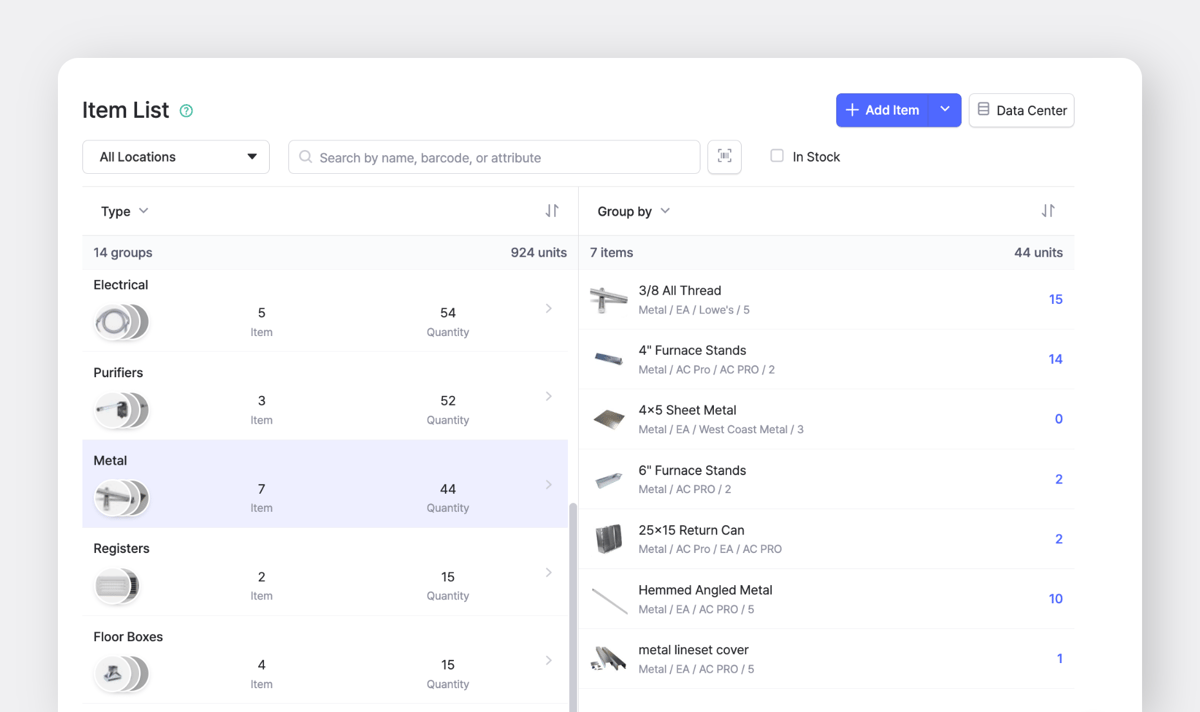

#1) Use Multiple Locations

Teams can create separate locations for each service vehicle, which makes it easier to check items in and out as technicians load or unload stock. Assigning each van its own location helps teams restock consistently, especially during seasonal rushes.

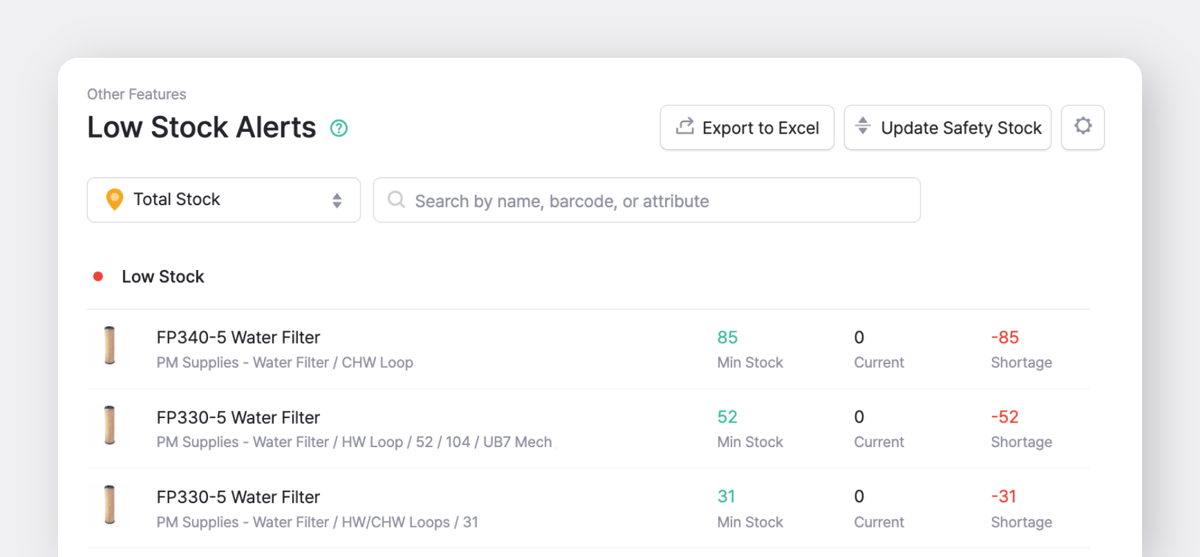

#2) Get Low Stock Alerts

When parts drop below a set quantity, BoxHero’s Low Stock Alerts notifies the team so they can restock before the shortage affects the day’s schedule. This is especially helpful for fast-moving items like capacitors, contactors, fuses, and filters.

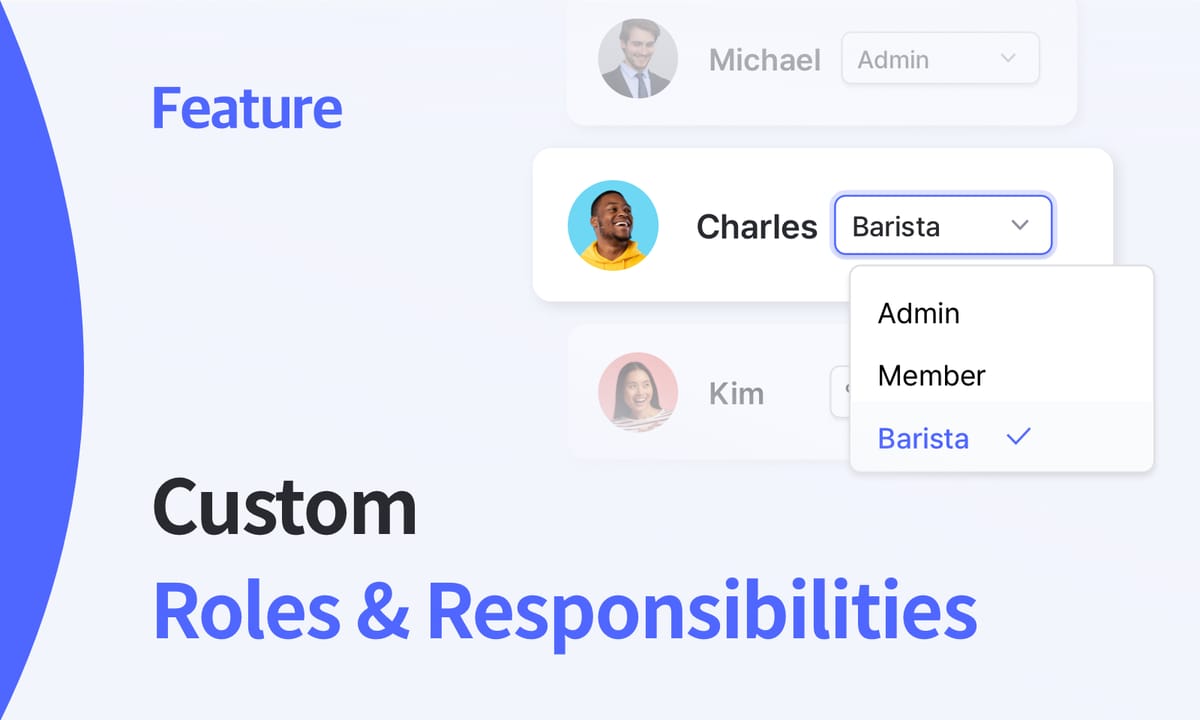

#3) Set Member Permissions

Roles and permissions help HVAC shops control who can view, edit, or update inventory. This keeps counts consistent and gives managers visibility without requiring every technician to make full inventory changes.

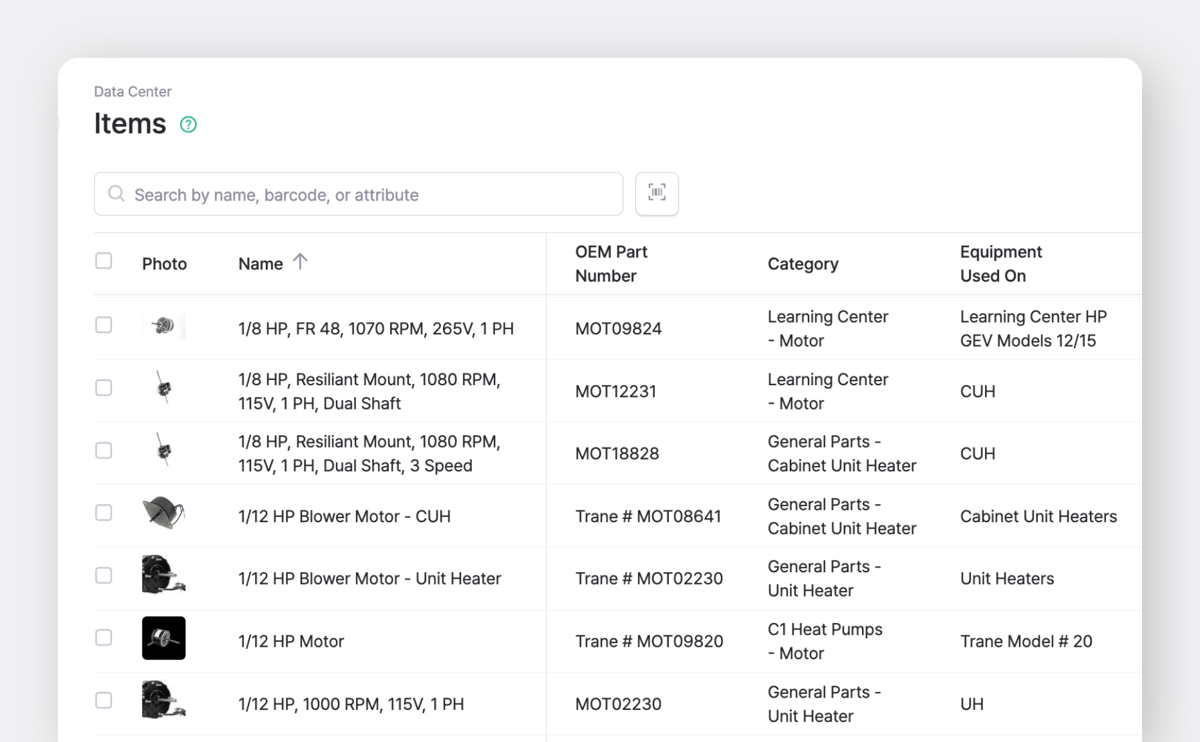

#4) Create Item Attributes

HVAC items often require detailed information to match replacements correctly. BoxHero supports custom attributes such as RPM, voltage, dimensions, and equipment compatibility. Items can also be grouped into categories like Electrical, Motors, Metal, Registers, or Purifiers to keep the warehouse organized.

#5) Record Supplier Details

Supplier information can be added directly in BoxHero so you have a single place to record lead times, preferred vendors, and purchasing notes.

If a supplier usually needs several days for certain motors or boards, you can note this in your partner directory. This helps with planning, especially when certain parts take longer to source during peak seasons.

Partners feature supports suppliers and customers, giving teams a clear place to reference availability and other notes.Final Thoughts

HVAC teams work in environments where preparation shapes the entire day. A technician with the right parts and materials completes the job faster and avoids unnecessary return visits.

The most dependable HVAC operations rely on consistent habits:

• Keep fast-moving parts visible

• Use pick lists for installations

• Maintain simple BOMs for standard install types

• Record supplier details and lead times

For HVAC businesses that want a simple, flexible way to manage stock across vans and warehouses, BoxHero fits naturally into existing workflows without requiring a large software implementation.