What is Safety Stock?

Q. Why is inventory management important?

A. Because every item in your inventory is MONEY. 💰

“Inventory is money sitting around in another form”

-Rhonda Adams, USA today

Inventory management and operations are always at risk due to unpredictable variables. So, is there any way to avoid that risk?

Today's article will discuss how using safety stock is beneficial to reduce your inventory and operations risk.

What is Safety Stock?

Safety stock is the extra quantity you hold in your inventory to avoid running out of products in unexpected situations. Many scenarios, such as rapid weather changes or a celebrity's social media post, can sudden increase customer demand and quickly deplete inventory. Although there is a risk of the excess product becoming dead stock, ordering extra amounts also give other benefits like price negotiations (economies of scale) and improve sustainability measures (less waste and transportation miles). Considering how the most sold out items can be one of the fastest ways to lose your customers, safety stock is something you should consider.

Safety stock keeps customers satisfied by maintaining a steady stock level. The addition inventory helps with ordering more items if your company makes a demand forecast error or underestimates popular items. You do not have to worry about relying on your suppliers to quickly deliver goods or turn away customers due to a low inventory level if you have enough safety stock.

Let us now check out how you can adopt safety stock to your business.

Importance of Safety Stock

- Protection against unforeseen supply variation - The main goal of safety stock is to keep enough inventory on hand in case of unexpected shortages. Because shortages can happen due to various reasons, it is recommended to keep extra stock in the back to be prepared. Especially if your items consist of non-perishables, keeping a safety stock is highly recommended.

- Avoid stock-outs to maintain customer satisfaction - Most importantly, safety stock has the potential to play a significant role in meeting customers' needs. Managing inventories and avoiding stock-outs provides ample supply to satisfy loyal customers. Therefore, keeping a surplus of quantity as safety stock can help the company to manage customer satisfaction.

- Inaccurate demand estimation - Although predicting inventory based on customer demand is crucial for all businesses, accurately forecasting for inventory management does not always work. Even if a company has experience or not, there is still a margin of error where prediction might not be successful. Therefore, it is recommended for businesses to be aware of tracking safety stock levels.

- Prevention against price fluctuations - Restocking inventories in an emergency will cause additional expenses since factories, shipment, and management must be rushed. Aside from this, once market price changes, it can cause the cost of your goods to increase unexpectedly. This results in a lack of raw material prices, unexpected market demand increases, and new competitors. If you have enough safety stock during these unforeseen situations, you may avoid the higher costs of item buying price without losing sales.

Calculating Safety Stock

Although there are many ways to calculate Safety Stock, the general safety stock formula will helps you find out the optimal number of products that you must maintain.

Safety Stock = (Max Daily Sales x Max Lead Time in Days) - (Average Daily Sales x Average Lead Time in Days)

* Lead Time is a product’s manufacturing time from the beginning to the end.

Let us look at the example below to understand the calculation of safety stock.

If we put the above values to the safety stock equation of the above, (30 x 7) – (20 x 4) = 130. As a result, company A will need a safety stock of 130 units.

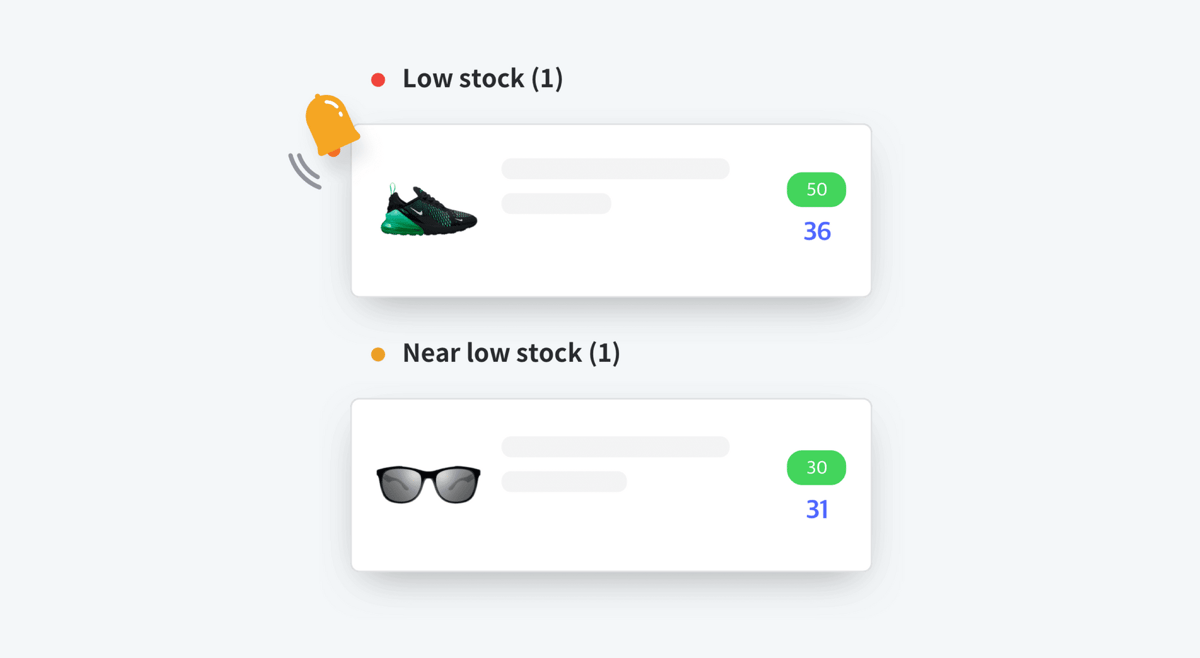

Low Stock Reminder

Low stock reminders help you to protect your business from stock fluctuations. The feature sends a stock alert notification to help you with reordering and prevent stock outs.

Start your inventory management with BoxHero and set a low stock reminder to improve your sales.

Optimize your Safety Stock with BoxHero

BoxHero supports ideal features for managing inventory, including:

📜Organize products by 'Categorizing' them according to your needs.

✔ Check your inventory status of reordering with 'Analysis' feature.

🔎Identify item's 'Low Stock' and view current stock status.

║▌Generate, scan, and print 'Barcodes' can all be processed quickly.

🧾Easy to create 'Purchase Orders' as well as invoice statements and analyze sales.

☁ BoxHero is a cloud-based inventory management system where you can create and share transaction with your team anywhere, anytime.

Having difficulty managing your inventory? Try BoxHero now.

BoxHero is an easy inventory management solution for everyone.

BoxHero's various smart features suit all industries and businesses.

Start inventorying right now with BoxHero!