Reorder Point Formula: Calculate With Confidence (No Math Degree Required)

Have you ever reached for your favorite cereal only to find an empty box? Or worse, have you ever run out of a critical part in your business and had to shut down production while waiting for a new shipment?

Effective inventory management requires knowing both how much to order and when to place that order. The reorder point formula provides a structured approach to these situations.

What’s a Reorder Point?

A reorder point is the inventory level at which you need to place a new order. When your inventory drops to this specific number, it's time to contact your supplier and get more items on the way before running out of stock.

Think of it as a warning system that tells you: "Order now or you'll run out before the next shipment arrives!"

For business owners and inventory managers, knowing when to reorder is just as important as knowing how much to order. Set your reorder point too high, and you'll tie up cash in excess inventory. Set it too low, and you risk stockouts that can upset customers or stop production.

The Reorder Point Formula Explained

The good news is that calculating your reorder point doesn't require advanced math. The basic formula is:

Let's break this down into plain language:

- Lead Time Demand: The amount of inventory you expect to use during the lead time (from order placement to delivery)

- Safety Stock: The buffer or extra units you keep on hand to handle unexpected situations, like a delivery day or a sudden spike in demand

That's it! Just two simple components are combined to tell you exactly when to place your next order.

This formula can also be expressed as:

= (Average Daily Usage × Lead Time in Days) + Safety Stock

Where:

- Average Daily Usage: How many units you typically use or sell each day

- Lead Time: How many days it takes for new inventory to arrive after you place an order

Both formulas get you the same answer–the first one simply consolidates average daily usage and lead time into a single concept called “lead time demand.”

How to Calculate Lead Time Demand

Lead time demand is the first major component of the reorder point formula. It answers the question:

"How much inventory will I use while waiting for my new order to arrive?"

This is the most important element in the formula.

Understanding Lead Time

Lead time is the total time from when you place an order until the items arrive at your warehouse and are ready to use. This typically includes:

- Time for your purchase order to be processed

- The supplier's production or picking time

- Shipping transit time

- Your receiving and stocking time

To determine your lead time:

2. Calculate the average of these times.

3. If you want to be extra careful, use the longest recent lead time instead of the average.

For example, if your last three orders took 5, 6, and 7 days to arrive, your average lead time would be 6 days.

Calculating Average Daily Usage

Your average daily usage (or consumption rate) is how many units of an item you typically use or sell each day. To calculate it:

- Look at your sales or production data for a meaningful period (like the last 30-90 days).

- Count the total number of units used during that period.

- Divide by the number of days in the period.

For example, if you sold 300 units over the last 30 days, your average daily usage is 10 units (300 units ÷ 30 days).

Putting Them Together

Once you have both numbers, multiply them to find your lead time demand:

Using our examples:

Lead Time Demand = 10 units per day × 6 days = 60 units

This means you'll need approximately 60 units to cover normal operations during your lead time.

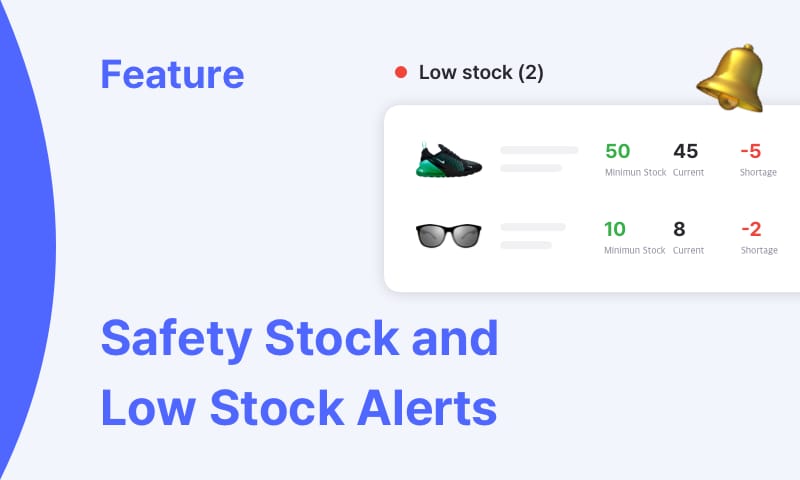

Understanding Safety Stock

Safety stock is your insurance policy against unexpected events like:

- Sudden spikes in demand

- Supplier delays

- Quality issues requiring returns

- Transportation problems

It's the buffer that helps you avoid stockouts when things don't go as planned.

How to Calculate Safety Stock

For small businesses, a direct approach to safety stock is to determine how many extra days of supply you want to keep on hand, then multiply that by your average daily usage:

For example, if you want a 3-day buffer with 10 units of daily usage:

Safety Stock = 10 units per day × 3 days = 30 units

Factors Affecting Your Safety Stock Level

How much safety stock you need depends on several factors:

- How critical the item is: Higher safety stock for items that would shut down operations if missing

- Demand predictability: More variable demand requires higher safety stock

- Supplier reliability: Less reliable suppliers require higher safety stock

- Seasonality: Items with seasonal demand may need varying safety stock levels throughout the year

- Storage costs: Expensive or perishable items may warrant lower safety stock

Step-by-Step Guide to Calculate Your Reorder Point

Now, let's put everything together with a complete example:

Step 1: Gather Your Data

Let's say you run a coffee shop and need to calculate the reorder point for your house blend coffee beans:

- You use approximately 5 pounds of beans per day

- Your supplier typically takes 7 days to deliver after you place an order

- You want to keep 3 extra days of supply on hand for safety

Step 2: Calculate Lead Time Demand

- Lead Time Demand = Average Daily Usage × Lead Time

- Lead Time Demand = 5 pounds × 7 days = 35 pounds

- During the 7-day lead time, you expect to use 35 pounds of coffee beans.

Step 3: Calculate Safety Stock

- Safety Stock = Average Daily Usage × Safety Days

- Safety Stock = 5 pounds × 3 days = 15 pounds

- Your safety buffer is 15 pounds of coffee beans.

Step 4: Calculate Reorder Point

- Using our primary formula:

Reorder Point = Lead Time Demand + Safety Stock - Reorder Point = 35 pounds + 15 pounds = 50 pounds

So, you should place a new order for coffee beans when your inventory drops to 50 pounds. This ensures you'll have enough to cover the lead time plus a safety buffer.

Reorder Point in Action: Real Business Examples

Retail Store Example

A clothing boutique sells an average of 8 units of their bestselling T-shirt each day. Their supplier takes about 10 days to deliver new inventory, and they keep a 5-day safety stock.

• Safety Stock = 8 units/day × 5 days = 40 units

• Reorder Point = 80 units + 40 units = 120 units

When the store's inventory of this t-shirt drops to 120 units, they place a reorder.

Manufacturing Example

A furniture manufacturer uses 25 packages of wood screws daily. Their hardware supplier has a lead time of 4 days, and they maintain a 2-day safety stock.

• Safety Stock = 25 packages/day × 2 days = 50 packages

• Reorder Point = 100 packages + 50 packages = 150 packages

The manufacturer should reorder screws when they have 150 packages left in inventory.

Common Mistakes When Setting Reorder Points

1. Using Outdated Data

Market conditions, customer preferences, and your business itself will change over time. Regularly update your usage rates and lead times to ensure your reorder points remain accurate. Tracking the right Inventory Management KPIs can help you identify when it's time to recalculate your reorder points.

Review your reorder points at least quarterly. For fast-moving or seasonal items, you may need monthly reviews to stay ahead of changing patterns.

2. Ignoring Supplier Variability

Even the most reliable suppliers have occasional delays. If your supplier's lead time varies significantly, consider using the longest reasonable lead time in your calculations rather than the average.

3. Not Adjusting for Growth

If your business is growing steadily, your historical usage data might underestimate future needs. Consider incorporating your growth rate into your calculations.

4. One-Size-Fits-All Safety Stock

Not all inventory items require the same safety stock level. Critical items that would halt operations might need a larger buffer, while less essential items might need less.

5. Forgetting About Minimum Order Quantities

Some suppliers require minimum order quantities (MOQs). Your reorder point calculation tells you when to order, but make sure your order quantity meets your supplier's minimum requirements, too!

Tools to Automate Your Reorder Point Calculations

Manually tracking inventory levels and calculating reorder points can be time-consuming. Fortunately, several tools can help automate this process:

1. Inventory Management Software

Dedicated inventory management systems like BoxHero can automatically track your inventory levels, calculate reorder points, and even trigger alerts when it's time to place an order. These systems often include features for:

- Setting custom reorder points for each product

- Automatically generating purchase orders

- Tracking supplier lead times

- Analyzing usage patterns

2. Spreadsheet Templates

If you're not ready for dedicated software, spreadsheet templates can help organize your calculations. Create columns for:

- Product name/SKU

- Current inventory level

- Average daily usage

- Lead time

- Safety stock

- Calculated reorder point

- Minimum order quantity

Update your current inventory regularly and use conditional formatting to highlight items that have reached their reorder point.

3. ERP Systems

Enterprise Resource Planning (ERP) systems integrate inventory management with other business processes like purchasing, sales, and production planning. These comprehensive solutions can calculate reorder points while considering broader business factors.

Special Considerations for Different Business Types

Seasonal Businesses

If your business experiences predictable seasonal fluctuations, you'll need to adjust your reorder points throughout the year. Consider:

• Increasing safety stock before peak seasons

• Reducing safety stock during off-seasons to minimize carrying costs

Just-In-Time Operations

If you operate on Just-In-Time (JIT) principles, you'll typically aim for minimal inventory levels. In JIT systems:

• Safety stock is often minimal

• Supplier relationships become especially critical

• More frequent, smaller orders replace fewer, larger orders

E-Commerce Businesses

Online retailers often face unique inventory challenges:

• Customer expectations for fast delivery

• The need to balance inventory across multiple fulfillment centers

• Potentially higher safety stock requirements to maintain service levels

When learning how to determine the reorder point for e-commerce products, it's essential to consider these factors in your calculations to ensure you maintain optimal stock levels across all sales channels.

Conclusion

The reorder point formula gives you a practical way to determine when to place new orders, helping you balance the risks of stockouts against the costs of carrying excess inventory. IBM explains that inventory optimization minimizes holding costs by maintaining optimal stock levels, freeing up working capital for other business needs.

Remember, the basic formula is:

Or in its expanded form:

= (Average Daily Usage × Lead Time in Days) + Safety Stock

By calculating and implementing appropriate reorder points, you can:

• Avoid tying up excessive cash in unnecessary inventory

• Reduce the time spent on emergency orders

• Create a more predictable purchasing process

With practice, calculating reorder points will become second nature, helping you maintain optimal inventory levels without breaking a sweat.

RELATED POSTS