How to Set Up Inventory Management in a Small Business (Even with No Experience)

If you run a small business, you’re already managing inventory in some way. Maybe you keep supplies in the back of your store. Maybe it’s a few bins in your garage or a shelf in your kitchen.

Whatever the setup, knowing what you have, what’s running low, and what’s moving fast helps you make better decisions every day.

This beginner-friendly guide breaks down how to get started with inventory management—even if you’ve never done it before. You don’t need fancy tools or a technical background. Just a few simple steps to help you stay in control of your items as your business grows.

Inventory: Not Just for Warehouses

Inventory management isn’t just for big-box retailers or warehouse operations. It’s a core part of how small businesses run. Yet nearly 46% of small‑to‑medium businesses don’t track their inventory or still rely on outdated manual methods.

"If your business uses, sells, or stores physical items in any form, you're already managing inventory."

When you don’t track your items, you risk buying more than you need, running out of key products, or simply losing time trying to figure out where things are.

A study focusing on SMEs found that inventory level management had a statistically significant impact on business performance (β ≈ 0.30). This suggests that even modest improvements in tracking and stocking can yield measurable benefits.

— The Standford Journal

Developing a basic inventory system allows you to make decisions based on actual data. It also reduces manual errors and gives you a better understand of how your resources are being used. You don’t need to start with a large system, but even a small, consistent approach can have a measurable impact.

What Inventory Looks Like in a Small Business

Inventory doesn’t always look like pallets stacked on shelves or rows of labeled bins. In small businesses, inventory often takes the form of supplies tucked under counters, materials stored in backrooms, or items distributed across multiple locations (including personal spaces like garages or home offices).

To build a usable system, it helps to redefine what counts as inventory in your context. Think beyond finished goods or retail products. For example:

- A café tracks cups, beans, milk, and syrups.

- A salon logs hair products, tools, and retail items.

- A craft seller monitors finished goods, supplies, and packaging.

Inventory can include any physical item that supports the delivery of your product or service. If it has a cost, takes up space, and is replenished over time, it belongs in your inventory records.

Businesses often run into problems when these types of materials are scattered across different locations or tracked inconsistently. Creating a unified view, even if it's basic at first, is the first step toward managing resources more effectively.

Map Your Workflow: How Do Your Items Move?

Choosing a spreadsheet or inventory tool too early can lead to workarounds that don’t match how your business actually operates. Before you invest time in any tracking system, take a close look at how items flow through your business.

Break this into three stages:

- Receiving: Where does inventory come from? Identify your suppliers, delivery schedules, and how items are received and stored. If you make your own items, document your production process and input materials.

- Storage: Where are items kept? Are they in fixed locations, shared spaces, mobile setups like delivery vehicles, or offsite units? Define these storage areas clearly so that items are easy to locate and count.

- Usage or Sale: How are items used or sold? Track how stock leaves—through sales, service jobs, consumption, or loss. Include edge cases such as returns, damaged goods, or internal use.

Documenting this workflow in detail gives you a clearer picture of your current operations and helps identify points where stock information is most likely to be missed or misrecorded.

Step 1: Build a Clear, Usable Item List

Every inventory system starts with a list. This isn’t about capturing every last detail, but creating a working reference for the items that matter most to your business.

Start by listing what you regularly purchase, sell, or use. A strong item list should include:

- Clear names: Use terms your team and customers already understand. Avoid internal codes or abbreviations that only one person knows.

- Categories or groups: Group items in ways that make sense for your business. For example, a retail store might separate items by type or brand, while a service business might sort materials by job function.

- Optional details: Include details such as size, color, or packaging format, especially if you carry similar items in multiple variations.

Start with your most commonly used items. You can build out the rest over time as your system takes shape.

Step 2: Track High-Priority Items First

You don’t need to track your entire inventory at once. Instead, begin with the items that impact your operations the most.

These typically fall into one of three categories:

- High-value items (high cost)

- Frequently depleted items (stock that runs out often)

- Bestsellers (high-demand items)

Even if you only start with a dozen products or materials, the value of knowing their status clearly outweighs the time spent maintaining a larger, unfocused list. Once this core set is in place, expanding your tracking to include more categories becomes easier and more useful.

Step 3: Choose a Tracking Method That Works

There’s no single “right” way to track inventory. Choose a format that’s practical for your current needs and sustainable with your available time and staff.

Here are a few options:

- Paper notebook or whiteboard: Great for daily logs in a small space.

- Spreadsheets: Flexible, especially if you already use Excel or Google Sheets.

- Inventory software: Helpful if you want automated updates, mobile access, or team collaboration.

If you’re just starting out, go with what’s easiest to update—you can always upgrade later. The best system is one you’ll actually use consistently.

Step 4: Make Inventory Updates a Routine

One reason small teams fall behind on inventory is that it’s treated as a separate task, rather than part of the regular workflow. But small, frequent updates are easier to manage than monthly overhauls.

Instead of setting aside time once a month for a full audit, incorporate smaller actions into your daily or weekly operations:

- At the end of each day: Note what was used, sold, or moved.

- Weekly: Restock and check fast-moving items.

- Monthly: Do a quick count or spot-check to catch discrepancies.

If your team already uses a closing routine or daily checklist, consider adding inventory tasks directly to those processes.

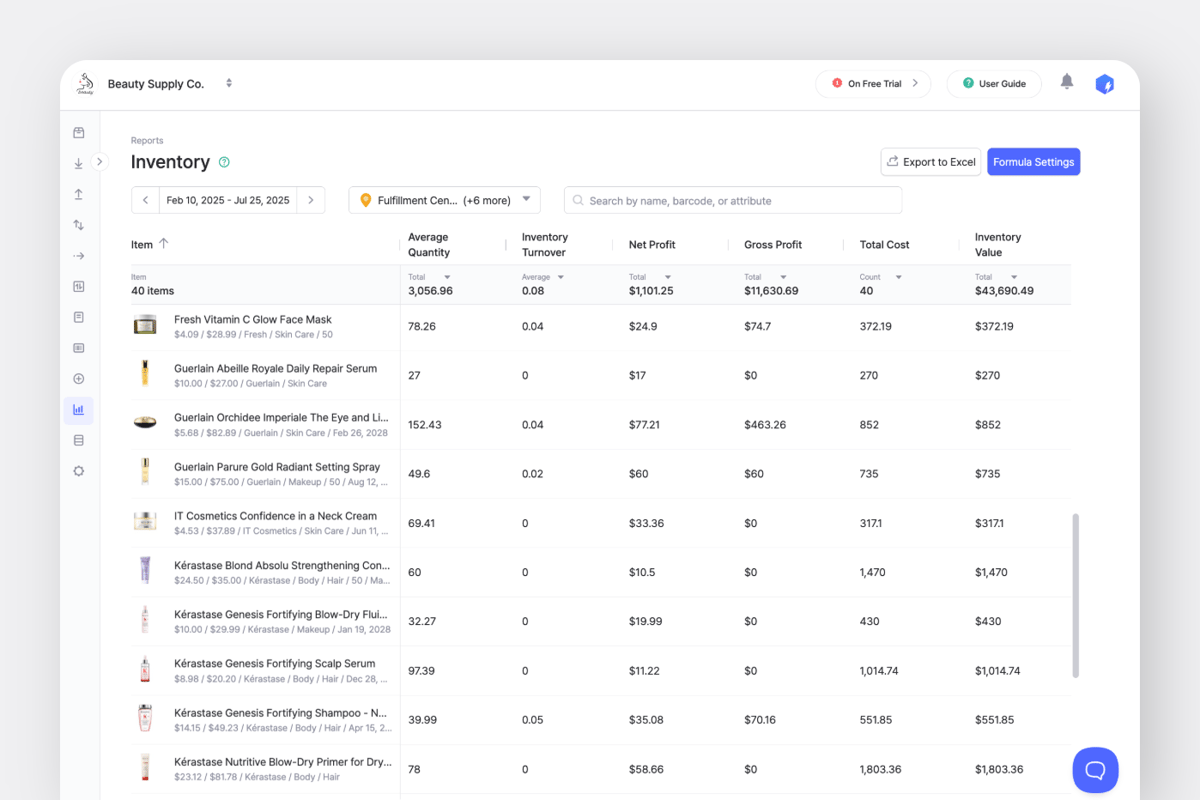

Step 5: Focus on Data That Helps Make Decisions

Inventory tracking isn’t about collecting as much data as possible. The goal is to monitor the right information so you can respond to real needs quickly.

For most small businesses, these three areas are a good place to start:

- Quantity on hand: Know how much you have available at any given time.

- Stock movement: Track how often items are being used, sold, or replaced. This helps identify patterns over time.

- Reorder signals: Recognize when it’s time to restock. That might mean a preset threshold or simply keeping notes on usage trends.

Even a simple note like “we go through 100 paper cups a week” helps you stay ahead of stockouts. You can better predict what to order, what to pause, and what to watch more closely.

When Should I Upgrade My Inventory System?

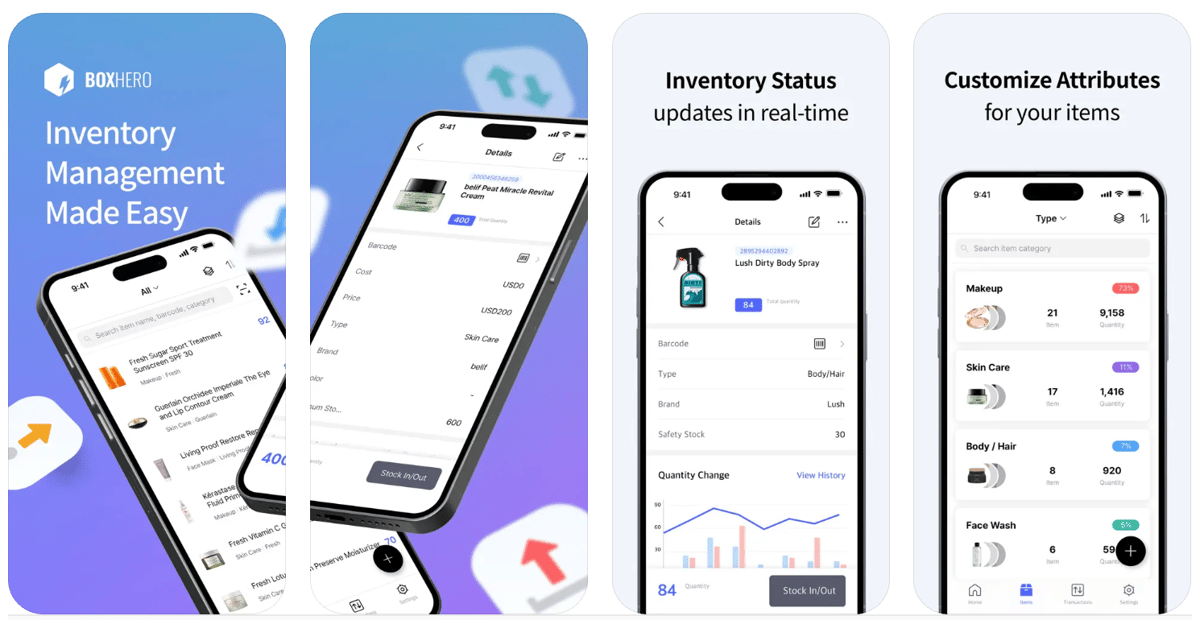

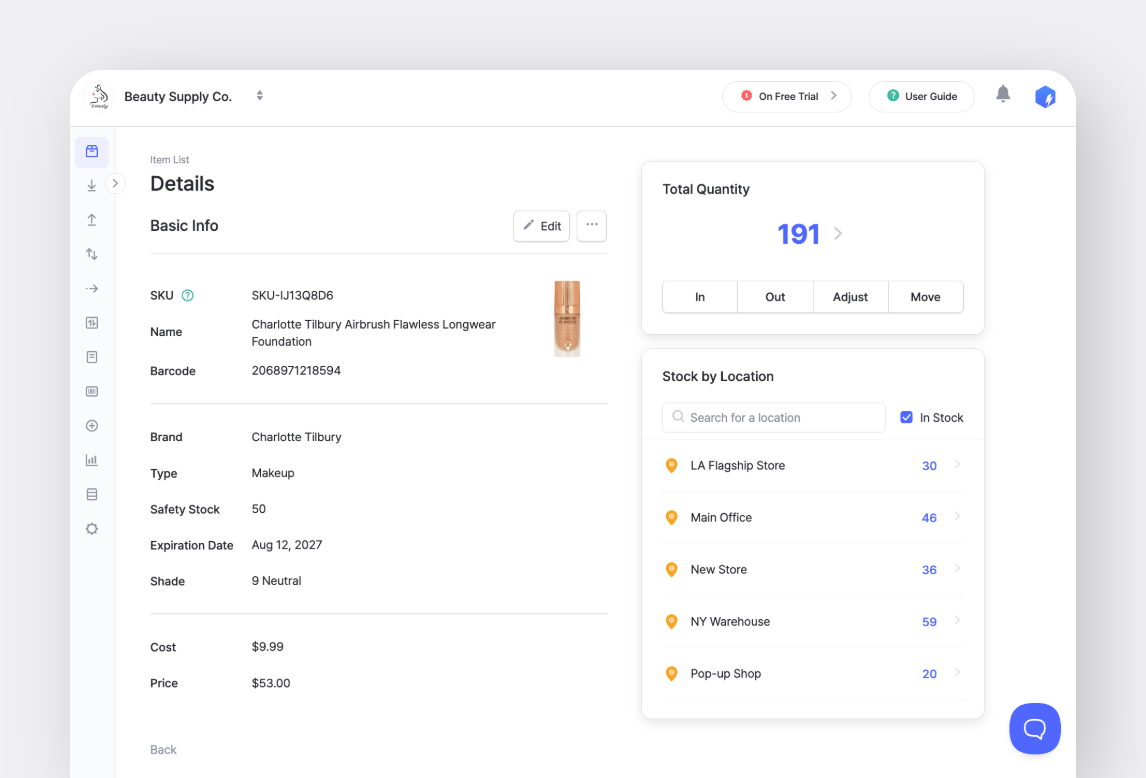

As your business grows, you may find that basic tools no longer meet your needs. You might reach a point where you want:

- Shared access for your team

- Low stock alerts

- Barcode scanning

- Reports on sales and usage trends

At this stage, inventory software becomes a more valuable investment. Look for a platform that’s easy to get started with, works well on mobile, and offers features like barcode scanning, team access, and useful reports you can actually use.

Conclusion

Building an inventory system doesn’t require a full-time manager or a complete overhaul of your current setup. The most important step is simply getting started with the items that matter most. As you develop consistent habits and adjust your process over time, your system will become a reliable part of how you run your business.

If you're looking for a simple, scalable tool that’s built for small teams, BoxHero offers an easy way to get started. You can track inventory from your phone, invite team members, and keep your stock under control.

Inventory may seem like a behind-the-scenes task, but it has a direct impact on your time, your spending, and your ability to grow. A little structure now can save hours down the road.

Sign up for BoxHero to get a free 30-day trial of all features. It’s simple, mobile-friendly, and designed to grow with your business.

RELATED POSTS