Supplier Lead Time: How to Measure, Manage, and Improve

Supplier lead time is one of the most important numbers in inventory management. It tells you how long it takes for items to arrive after you place an order with your supplier.

Even a small change in lead time can affect how much stock you carry, when you reorder, and whether you run into shortages (or not).

In this article, we’ll explain how supplier lead time works, why consistency matters more than averages, and what you can do to measure and improve it. We’ll also look at recent trends and show how BoxHero can help you track lead times in your everyday workflow.

What is Supplier Lead Time?

Supplier lead time is the time between sending a purchase order to your supplier and receiving the items at your location.

The Association for Supply Chain Management (ASCM) defines lead time as the "elapsed time from order to receipt."

In practice, it’s best measured as: the number of calendar days from placing a purchase order to the moment the goods are physically received and available for use. Supplier lead time gives you a clear, consistent way to plan your reorders.

The Risk of Unpredictable Lead Times

Average lead time alone doesn’t tell the whole story. Two suppliers with the same quoted lead time (let's say, 20 days) can behave very differently depending on consistency if one consistently delivers in 19–21 days and the other swings between 10 and 40 days.

Variability creates uncertainty, and uncertainty forces you to keep extra stock. Research shows that reducing lead time variability variability often has a bigger impact on lowering inventory levels than reducing the average lead time by a few days.

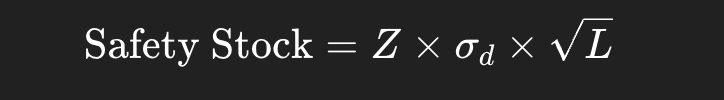

Safety stock formulas reflect this directly, because buffers depend on demand uncertainty and variability in lead time (we’ll put this into calculation in a moment).

Recent Trends in Supplier Lead Times

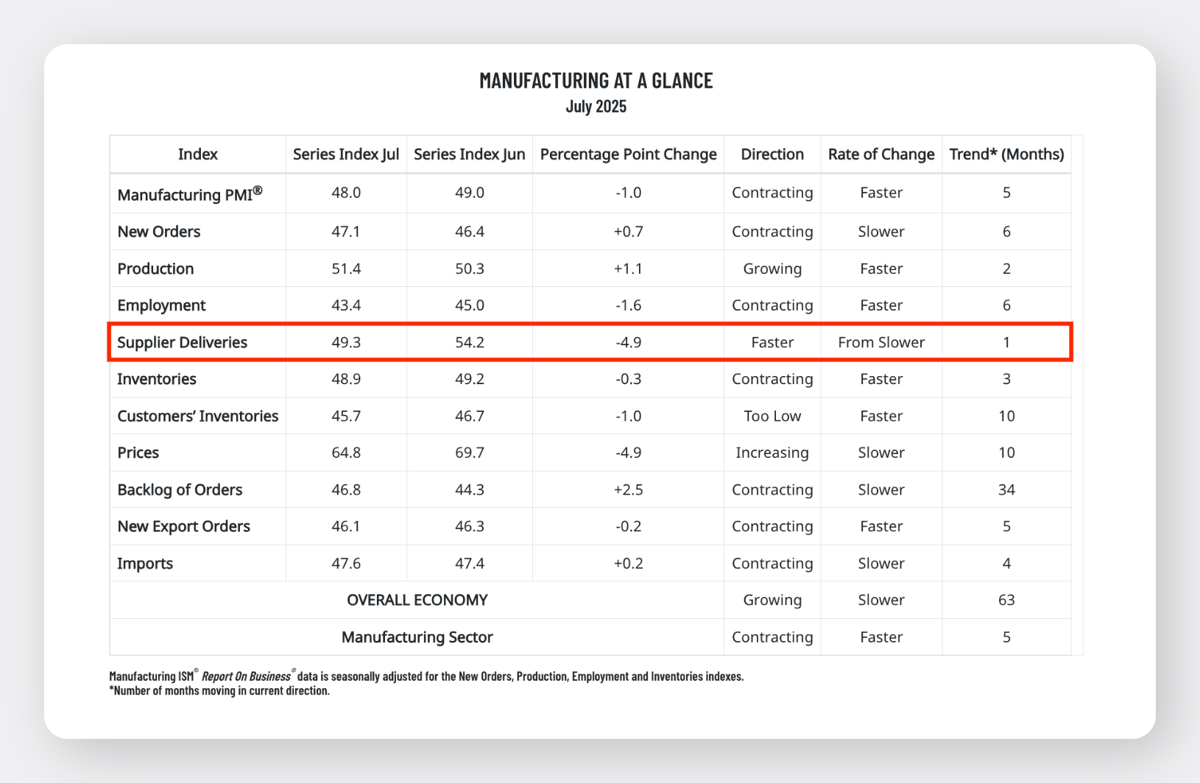

Supplier lead times change over time, often because of broader economic and logistics factors. Some current data:

- ISM Supplier Deliveries Index dropped to 49.3 in July 2025, which indicates that deliveries were faster than in June (Note that this index is inverted; above 50 means slower deliveries, below 50 means faster).

- Ocean transit times from China have also ticked down recently. Flexport data shows that average transit to the U.S. East Coast now averages 53.3 days, down from 56.9 days.

- In contrast, some industries remain under pressure. For example, U.S. gas-turbine equipment lead times are still 5 years or more, according to Reuters.

The lesson is simple: don’t assume your lead times are fixed. Keep measuring and updating your expectations.

How to Measure Supplier Lead Time

To measure lead time correctly:

- Capture timestamps when a purchase order is placed and when items are received.

- Measure at the item–supplier level. Lead times often vary by item, even with the same supplier.

- Track the following metrics:

2. Lead time variability*

3. OTIF (% On-Time, In-Full)

4. Expedite ratio**

*Lead time variability is a standard deviation.

**Expedite ratio is how often orders need to be rushed.

This data provides a clearer picture of which suppliers are reliable and which ones put your inventory at risk, so make sure you measure theses regularly!

How to Calculate Safety Stock with Lead Time

Safety stock is the buffer you keep to protect against uncertainty. Lead time plays a big role in how much buffer you need.

- Lead time demand =

average daily demand×average lead time - Safety stock =

Z×standard deviation of demand×√(lead time)

where Z is your service level factor (e.g., 1.64 for ~95%).

Example

Let's take a look at an example. We'll try to find the safety stock and reorder point in units, based on the following situation:

- Lead time demand = 20 × 14 = 280 units

- √L = √14 ≈ 3.74

- Safety stock ≈ 1.64 × 6 × 3.74

- First, 6 × 3.74 = 22.45

- Then, 1.64 × 22.45 ≈ 36.80

So, the results are:

- Safety stock ≈ 37 units (round up).

- Reorder point ≈ 280 + 37 = 317 units.

Reducing lead time variability lowers safety stock significantly, which is often more impactful than reducing the average. Plus, it frees up cash and storage space!

Strategies to Reduce Supplier Lead Time

Fortunately, lead time is something you can influence. We'll share some practical ways to shorten or stabilize it—each of these strategies reduces either the length or the unpredictability of your lead time:

- Place smaller, more frequent orders to avoid batching delays.

- Negotiate supplier lead time agreements for clear service levels. Set delivery-date expectations with clear penalties or credits.

- Consider vendor-managed inventory (VMI) or consignment. For critical items, suppliers can hold stock closer to you.

- Nearshore select products (i.e. move production closer) if transit times are too long.

- Adjust minimum order quantities (MOQ) and packaging. Large MOQs may delay production.

How BoxHero Helps with Supplier Lead Time

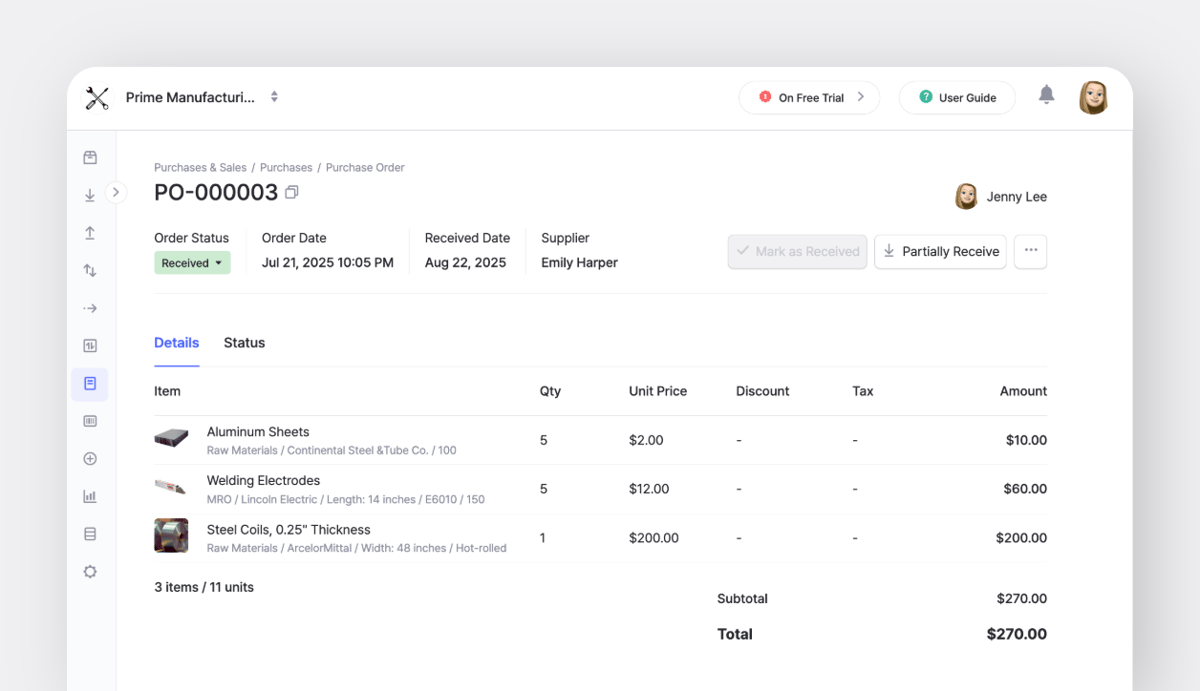

BoxHero makes it easier to track and manage supplier lead times by:

- Recording expected delivery dates to purchase orders.

- Capturing actual receipt dates when items are scanned in.

- Setting safety stock levels based on your real data.

Checklist: Managing Supplier Lead Time

Here’s a simple checklist you can run this week:

- Review the last 6 months of receipts.

- Calculate average lead time and variability for your top items.

- Recalculate safety stock using your actual data.

- Identify suppliers with the biggest gaps between promised and actual lead times.

- Start one conversation with a supplier to address those gaps.

They change with logistics capacity, macro demand, and trade policies.

Key Takeaway

Supplier lead time affects every part of your inventory decisions. By measuring it at the item–supplier level, tracking variability, and working with suppliers on practical improvements, you can reduce stockouts, free up cash, and build stronger vendor relationships.

BoxHero helps make this process easier by capturing the data you need and turning it into useful safety stock levels and supplier insights.

RELATED POSTS