How to Actually Improve Your Warehouse Picking and Packing

Picking and packing is one of those behind-the-scenes steps that customers rarely think about, yet it determines whether an order arrives on time, in good condition, and with the right items inside.

What might surprise you is how much of a warehouse’s budget is tied up in this process. Research shows picking and packing can account for over 50% of total operating costs.

This isn't just a local challenge either. The global warehouse picking market is growing by 10.8% each year, according to Grand View Research. It's a clear sign that businesses everywhere are investing in better ways to manage it.

In this article, we’ll break down how pick and pack actually works, the different methods businesses use, and the practical changes that can make your process faster, more accurate, and more cost-effective.

What Pick and Pack Actually Means

Pick and pack is the part of order fulfillment where inventory turns into an actual customer order. At its core, it has two distinct steps: (1) finding the right items in your warehouse and (2) getting them ready for shipment.

- Picking means locating and retrieving the items needed to fulfill customer orders. Workers walk through the warehouse, find where products are stored, scan barcodes for verification, and collect the correct quantities.

- Packing means checking those items, putting them in appropriate boxes or packaging with protective materials, and preparing them for carrier pickup.

It sounds simple, but the hidden costs are big.

Here's the real problem:

50-60% of picking time is spent walking between shelves rather than actually handling products. That means your workers might spend more time traveling through aisles than doing the actual work of grabbing items.

How you organize your warehouse layout, choose your picking methods, and structure your workflow directly impacts labor efficiency, operating costs, and customer satisfaction.

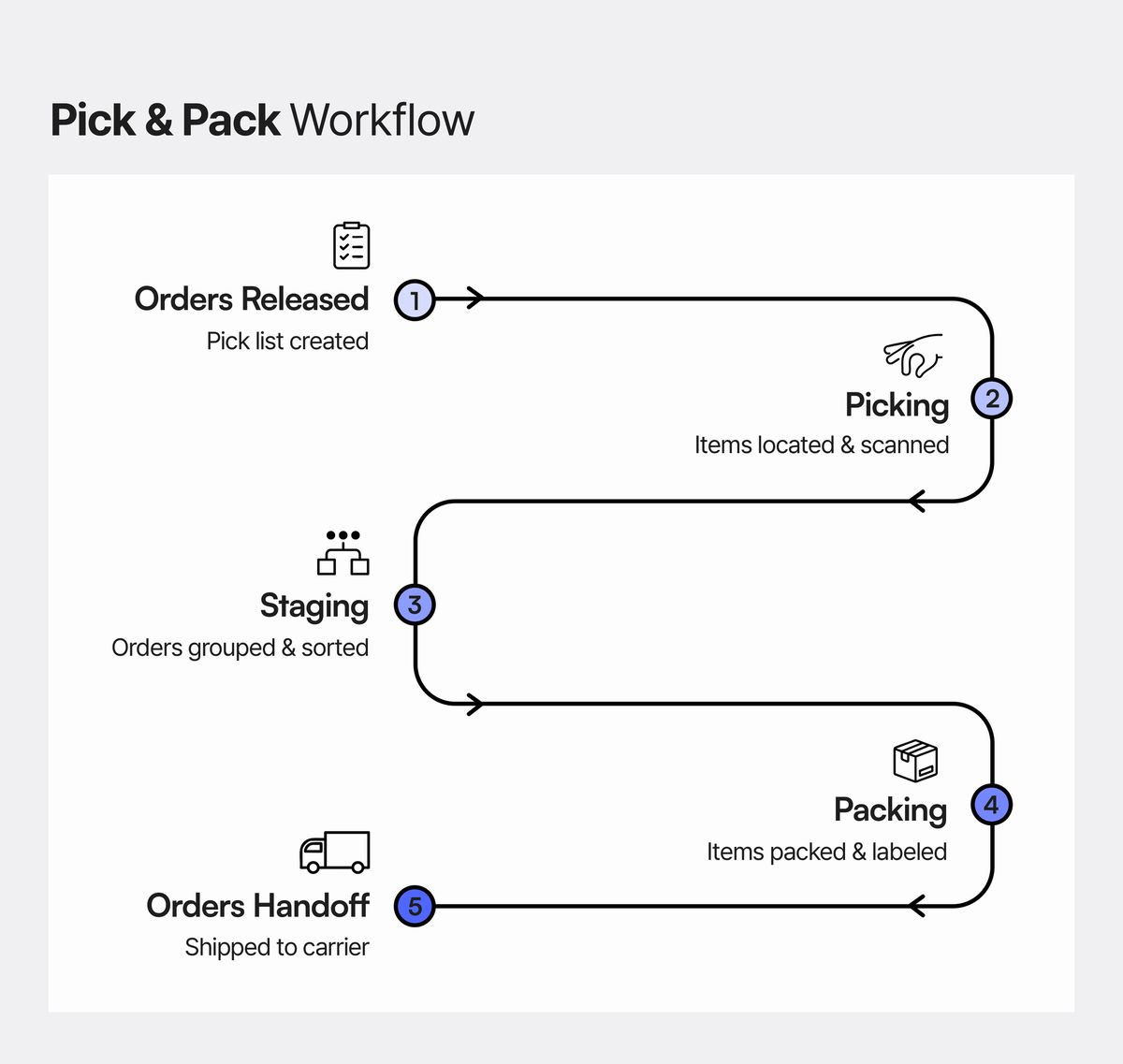

How the Pick & Pack Process Works

Before getting into optimization strategies, we need to better understand the standard workflow. Most fulfillment operations, large or small, follow these five core steps:

- Orders released: Digital or printed pick lists show workers exactly what needs to be picked and where items are located in the warehouse.

- Picking: Staff travel through storage areas, locating items and scanning barcodes to verification.

- Staging: Picked items are grouped by order or by warehouse zone.

- Packing: Staff verify item accuracy, place them into boxes or mailers filled with protective dunnage (cushioning materials), and apply shipping labels with carrier information.

- Orders handoff: Completed packages are passed to shipping carriers for final delivery.

Each step represents both an opportunity and a risk. Every touchpoint requires time, labor, and materials while introducing potential for errors.

A misplaced item during picking becomes a customer complaint. An incorrectly sized box during packing drives up shipping costs. Small mistakes compound quickly.

That’s why it's so important to treat pick & pack as a structured routine. A clear, repeatable pick and pack process reduces errors, keeps costs predictable, and ultimately gives customers a more reliable experience.

Choosing the Right Picking Method

Different warehouses use different picking strategies. The right choice depends on your order volume, warehouse layout, and product types. Here are the four main methods, from simplest to most complex:

1. Single Order Picking

One picker, one order, start to finish. This is the most straightforward approach, where one worker handles a complete order from beginning to end.

- How it works: A picker receives an order, walks through the warehouse collecting all items for that specific order, then moves directly to packing.

- Pros: Easy to track who did what. If there's a mistake, you know exactly where it came from. Great for maintaining quality control for high-value or fragile items and handling complex orders.

- Cons: Usually slower than other methods, so it works best for specialized orders rather than high-volume simple ones.

2. Batch Picking

One picker collects the same item across multiple orders in a single trip, then sorts to orders at the packing station.

- How it works: Instead of completing orders individually, workers pick all quantities of the same item needed across 50-100 orders at once using a picking cart. Items are then sorted by order at the packing station.

- Best for: Businesses with high order volume and overlapping product demand (many customers ordering the same items).

This method works really well when multiple orders contain the same popular items. Rather than visiting the same shelf location 50 times, workers make one trip and grab everything needed.

3. Zone Picking

The warehouse is divided into sections, with dedicated pickers assigned to each zone.

- How it works: Orders travel through multiple zones, and each picker retrieves items only from their designated area. All components then meet at a consolidation point for packing.

- Pros: Worker specialization means pickers become experts in their zones and know exactly where everything is (

+1to speed,+1to accuracy over time). - Cons: The challenge is making sure all zones finish simultaneously. Zone picking also requires more advanced tracking to monitor order progress across different zones or areas.

4. Wave Picking

Orders are grouped and processed during scheduled time blocks aligned with shipping deadlines.

- How it works: The warehouse processes batches of orders in scheduled "waves," typically timed around carrier pickup schedules. This approach combines elements of batch and zone picking within each wave.

- Best for: High-volume operations with predictable shipping schedules and multiple daily carrier pickups. Most small businesses don't need this level of complexity until they're processing 500+ orders daily.

Wave picking optimizes labor allocation around carrier pickup times and makes sure orders meet specific shipping cutoffs. However, it's more complex to manage and requires sophisticated coordination (a warehouse management software may be helpful here!) which may be overkill for smaller operations.

6 Ways to Optimize Your Pick & Pack Process

Now that you understand the different picking methods, let's look at practical strategies to improve the pick and pack process. These tactics will help you save time and cut costs cross your entire operation:

1. Move Top-Selling Items Near the Packing Area

Where you position products in your warehouse directly affects picking speed. High-velocity items (items that sell a lot) should be stored in easy-to-reach spots near the packing station, while slower-moving products can sit in less convenient locations.

"A" items (bestsellers) get the best spots, "B" items (moderate sellers) go in okay spots, and "C" items (slow sellers) use whatever space is left.

Review and adjust these locations regularly as sales patterns change.

2. Batch Orders with the Same Popular SKUs

Group orders containing identical popular items together before picking begins. This reduces the number of times workers visit each storage location and can dramatically cut picking time.

3. Standardize Walking Routes Through Aisles

The average newly constructed warehouse in the U.S. is roughly 181,370 square feet, and they keep getting bigger. As facilities expand, walking routes become even more important for maintaining productivity.

Effective route strategies:

- Design snake-like patterns for systematic picking

- Add strategic cross-aisles so workers can take flexible routes based on what they're picking

- Plan logical progression through zones to avoid backtracking

4. Scan at Both Pick and Pack Stations

A two-step verification process catches errors before they reach customers. Workers should scan items during picking to confirm accuracy, then scan again during packing as a final check.

5. Right-Size Your Packaging

Box size directly affects shipping costs and customer satisfaction. Oversized boxes waste money on materials and dimensional weight charges. Undersized boxes risk product damage.

Standardize a handful of box and mailer sizes that cover 90% of your orders. This helps reduce waste, lowers shipping fees, and speeds up packing decisions.

6. Protect Your Products

Balance product safety with packaging costs by standardizing your protective materials. Stick to one or two types of filler—like recycled paper or biodegradable padding—and create guidelines for when to use each.

A well-organized packing station has multiple protection options (bubble wrap, air pillows, foam, paper, etc.) with clear rules about which products need which level of protection based on fragility and shipping distance.

Putting It All Together

Here's the thing about picking and packing: you can't fix everything overnight, and you probably shouldn't try.

Most businesses see the biggest gains by tackling their worst bottleneck first.

- If workers are walking miles every day to pick orders, start there.

- If you're constantly shipping orders in boxes three times too big, fix your packaging system.

The expensive mistakes happen when businesses jump straight to fancy technology without fixing basic workflow problems first. A warehouse management system (WMS) won't help much if your bestselling products are stored in the back corner.

Start simple: watch your team work for a day and note where time gets wasted. Talk to your pickers about what slows them down. Sometimes the solution is as basic as moving your top 20 SKUs closer to the packing area!

For businesses ready to take the next step with inventory tracking, tools like BoxHero help you spot issues in real-time. But the software only works if your foundation is solid.

Your picking and packing process doesn't need to be perfect—it just needs to be better than it was last quarter. 😀

RELATED POSTS