What Is Stock Control? What It Is and Why It Matters

How to keep control of your warehouse despite fluctuations in demand, supply, and your business’ cash flow.

Have you ever wondered how food supermarkets manage their perishable inventory?

For instance, how do they buy just the right amount of fresh beef steaks to meet customer demand but not so many that unsold steaks go bad? If they don’t sell out, the money spent on buying and marketing those steaks is lost.

The aftermath of the COVID-19 crisis, widespread supply chain disruptions, shifting consumer behavior, and recent inflation have been challenging traditional inventory management strategies. In 2022 alone, U.S. retailers accumulated $78 billion more in inventory compared to the previous year.

One effective way to address inventory management issues is through stock control. This broad approach includes various methods, strategies, and best practices aimed at minimizing inventory costs while maximizing revenue and customer satisfaction.

Let’s explore how you can implement stock control and start reaping the benefits.

What Is Stock Control?

Stock control, also known as inventory control, is the process of monitoring and managing the quantity, location, and movement of goods that you plan to sell. Stock control ensures that the right amount of stock is available at the right time, minimizing excess inventory and preventing shortages.

What constitutes the "right amount" of stock can vary across business models and industries. As in the steak example above, certain products are perishable and cannot be packed and stored for future demand. In other industries, however, retailers may choose to sell unsold seasonal stock at steep discounts.

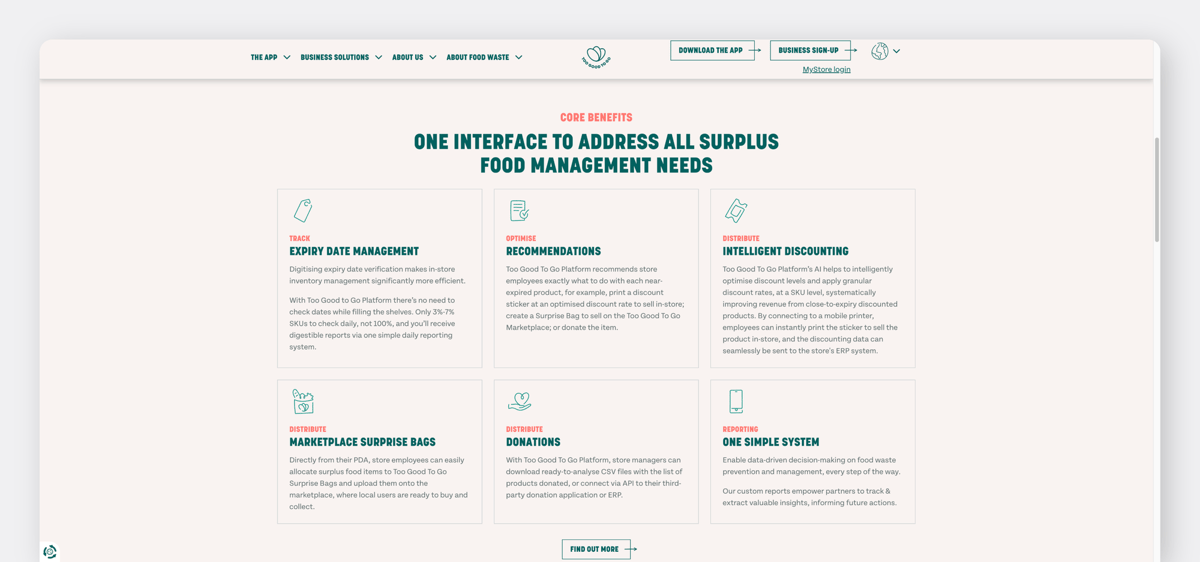

Packing and storing flip-flops until the next summer, or liquidating unsold steaks through a Too Good To Go–type company, illustrates how stock control strategies can take various forms.

Why Is Stock Control Important?

To understand why stock control is important, let’s bring the concept down to a personal level.

We make small “stock decisions” every day. Should I buy fresh chicken fillets or frozen ones? Frozen fillets last longer, helping you avoid frequent grocery trips. On the other hand, fresh meat tastes better in meals.

The stock decisions retail entrepreneurs face are similar—just on a much larger scale. You can’t simply buy a million units of your best-selling product and forget about inventory management (just like you wouldn’t buy a thousand chicken fillets and expect your grocery needs to be covered for the entire year).

Why not?

A) You’d get bored eating the same food every day.

In retail terms: your customers might lose interest in the product, so you need to anticipate and respond to shifting demand.

B) Even frozen meat eventually spoils and requires special storage conditions.

In retail terms: products in your warehouse may have a limited shelf life and require investment in storage infrastructure.

C) The money spent on a thousand chicken fillets could have been used for other things—like clothes, a new kitchen gadget, or a vacation.

In retail terms: money tied up in inventory could be invested elsewhere. Until those goods are sold, that capital is effectively “locked” in unsold stock.

To put it formally, the key factors that make stock control a priority in retail include the following:

▶︎ Reducing Inventory Storage Costs

Holding inventory costs money. You must pay for storage space and maintenance, maintain proper conditions, and hire staff to manage it all. Efficient stock control helps keep these costs down.

▶︎ Maintaining Healthy Cash Flow and Working Capital

Timely inventory turnover keeps the business financially strong and healthy. Put simply, when a company holds excess inventory, it ties up cash that could otherwise be used to support growth or operations, such as employee bonuses, new equipment, or marketing. Unsold stock keeps that capital “locked” until it is converted back into revenue.

▶︎ Improving Customer Experience

When you keep the right amount of stock on hand, customers are more likely to find what they’re looking for and leave your store satisfied. It starts with understanding demand and planning inventory accordingly.

Stock Control: Best Practices and Tips

Now that you understand what stock control is and why it’s important, let’s look at how to put that knowledge into action. These tips will help you manage your inventory more accurately and efficiently.

Tip 1: Run Regular Inventory Counts

Conducting regular inventory audits helps keep your stock records accurate and prevents issues. If the ERP says you have 100 items but you really have 87 on the shelf, your team might sell something that’s out of stock. Automated systems could also skip reordering, thinking you have enough.

"What is cycle counting?"

Cycle counting is a way to keep inventory accurate without shutting down your whole operation. Instead of counting everything at once (which can take forever), you:

- Pick one or two categories to check each day.

- Count just those items.

- Fix any mistakes you find.

- Repeat regularly, rotating through all categories until the whole store has been checked.

This way, you’ll always know how much there really is without needing to shut down or conduct full-store counts too often.

Tip 2: Understand and Plan for Demand Fluctuations

Consumer tastes can vary by season, region, trends, or even time of day. Understanding these patterns helps you stock more accurately.

Tip 3: Implement an Inventory Management System

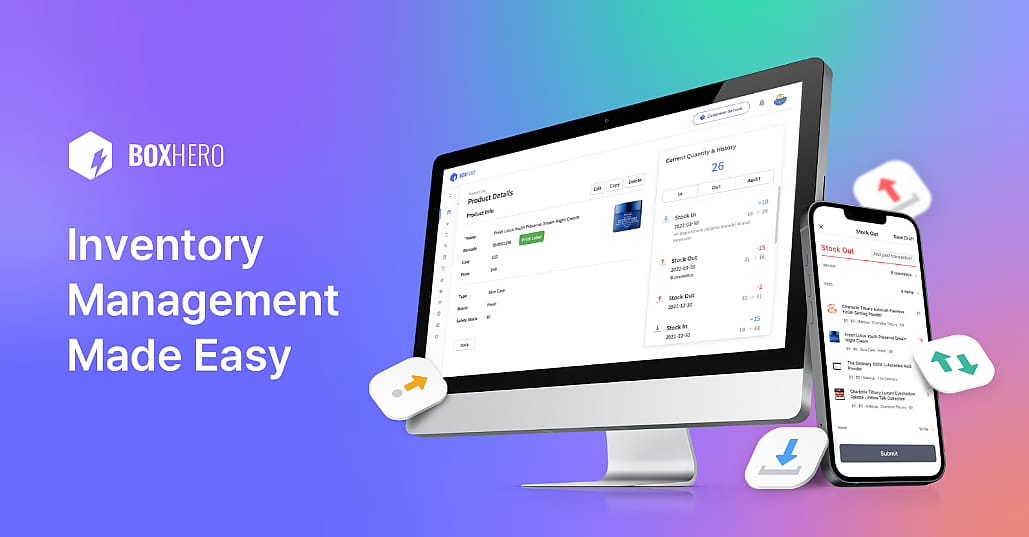

A digital inventory system can help you save time and reduce errors. It helps you track stock in real time, set up automatic reorder points, and connect with other tools in your tech stack.

• Import your item data from Excel and generate unique barcodes.

• Track inventory transactions for each item by scanning barcodes. All you need for scanning is a smartphone camera.

• You and your team can access BoxHero on the browser, phone, or tablet. It’s the perfect on-the-go solution for inventory tracking.

- Try it free on Android: Google Play

- Try it free on iOS: Apple App Store

Most Popular Stock Control Methods

In addition to the inventory tips we’ve already covered, there are also several common stock control methods used in practice. None of them are perfect or one-size-fits-all, but understanding these methods can help you build a stock control strategy that fits your business.

1. FIFO and LIFO

FIFO, which stands for First-In, First-Out, is a stock control principle that assumes that the oldest stock is sold first.

You might have noticed that in supermarkets older produce is often placed at the front so it sells before it expires. FIFO is especially helpful for managing perishable goods like food, cosmetics, or medication.

Related: FIFO: Basics, Benefits, and Tips

On the other hand, LIFO (Last-In, First-Out) is a stock control method where the newest stock is sold first.

LIFO may be preferred to FIFO in situations where:

• Price inflation is significant, and businesses want to reduce their tax burden by matching higher recent costs with current revenues.

2. Just-In-Time (JIT)

The Just-In-Time (JIT) approach focuses on keeping as little inventory on hand as possible. Items are ordered only as they are needed for production or sales, which reduces storage costs. However, it also increases reliance on accurate demand forecasting and dependable suppliers.

JIT works best if:

• Your demand is stable and predictable, based on historical sales patterns.

• You’re in a high-turnover industry, such as fashion, food, or tech, where holding excess inventory can become outdated or spoil quickly.

3. Min-Max Inventory Control

With the Min-Max method, you set two levels or thresholds for each item: a minimum (min) and a maximum (max) level. When inventory drops to or below the minimum level, a replenishment order is triggered—typically enough to bring stock back up to the maximum level.

IKEA is reportedly known to apply this technique in their stores, with inventory thresholds set at the individual store level. Given IKEA’s large store formats and high daily foot traffic, this approach makes perfect sense. They can reliably estimate the minimum and maximum stock levels needed for each product based on consistent, location-specific demand.

Related: What We Can Learn from IKEA’s Supply Chain

Min-Max Inventory works well when:

• Products are non-perishable, and can be held for longer periods without risk of spoilage or obsolescence.

• You manage a large number of SKUs, and want to automate restocking.

4. Economic Order Quantity (EOQ)

Economic Order Quantity, or EOQ, is an inventory management formula that helps you find the optimal order quantity that minimizes total inventory costs.

Calculating EOQ helps you strike a balance between the costs of ordering and holding inventory. These two cost categories typically work against each other. Ordering in larger quantities reduces the frequency of orders and lowers administrative costs per order, but it also increases storage needs and holding costs. EOQ helps identify the sweet spot where the total cost is minimized.

Here’s the formula:

Where:

• S = Ordering cost per order (e.g., admin costs, delivery fees)

• H = Holding cost per unit per period (e.g., storage, insurance, depreciation)

Example: If EOQ equals 100, that means ordering 100 units per restock is most efficient given your demand and costs.

EOQ may be applied:

• In manufacturing or wholesale, where non-perishable items, such as packaging materials or standard components, are ordered in bulk.

5. ABC Inventory Analysis

ABC Inventory Analysis is a technique that helps you prioritize your stock control efforts based on the value and the sales volume of your inventory. It sorts your items into three categories:

- A-items: High value, low volume. Require tight control and frequent review.

- B-items: Moderate value, moderate volume. Require balanced oversight.

- C-items: Low value, high volume (e.g., office supplies, basic accessories). Can be managed with simpler controls due to lower financial impact.

When to Use ABC:

• When your inventory budget and management bandwidth are limited

ABC analysis is particularly effective when used in tandem with automated inventory systems. These systems can set up different reorder points for different categories of products.

6. Vendor-Managed Inventory (VMI)

With Vendor-Managed Inventory (VMI), your supplier is responsible for monitoring and replenishing your stock.

Instead of you placing the orders, the supplier monitors your sales data and restocks as needed—based on pre-agreed rules. VMI is essentially a method of outsourcing inventory planning and replenishment to the vendor. In VMI:

- The vendor typically has real-time access to the buyer’s sales and inventory data

- The vendor decides when and how much stock to order based on shared data

VMI outsources the decision-making part of inventory management, while inventory ownership and physical storage remain with you, the retailer. This contrasts with other inventory outsourcing models like 3PL, where either storage, fulfillment, or full control of inventory operations is transferred to a third-party provider.

VMI is most suitable for:

• Grocery chains and supermarkets

• Businesses with strong supplier relationships and shared digital infrastructure

Which Method Should You Choose?

Each of the stock control methods above comes with its own strengths and trade-offs.

You don’t have to commit to just one—many businesses combine several techniques depending on the product category. For example:

▶︎ Apply EOQ for bulk materials

▶︎ Use ABC to prioritize high-value inventory

Start small and experiment with one or two models that match your current setup, then expand your strategy as your business grows.

Conclusion

At its core, stock control is about keeping the right amount of inventory on hand to meet customer demand without overstocking or running out.

In this guide, we’ve explored the idea of stock control and some of the most widely used stock control techniques, including:

• JIT — for minimizing storage by ordering only when needed

• Min-Max — for using thresholds to trigger reorders

• EOQ — for calculating the most cost-efficient order quantity

• ABC Analysis — to prioritize inventory based on value

• VMI — to outsource planning and let suppliers manage stock for you

Each method tackles the same big questions: When should I restock? How much should I buy? How do I keep inventory lean and customers happy?

Your business may benefit from using just one of these techniques—or combining several, depending on your product type, supplier relationships, and sales patterns. The right strategy depends on what you sell and how your business operates.

Let BoxHero Simplify Stock Control for You

BoxHero makes it easy to put these strategies into action.

Whether you’re tracking stock levels and setting reorder points or categorizing SKUs and syncing inventory across locations, you can manage it all in one place.

RELATED POSTS